As a seasoned professional in the boiler industry, I can provide insights on fire tube boilers, their uses, advantages, and disadvantages. In this article, I will answer the following questions:

As someone who has been working in the boiler industry for many years, I am very familiar with the fire tube boiler, which is a commonly used type of boiler. In this article, I will introduce you to the working principle, advantages, disadvantages, and maintenance of a fire tube boiler.

What is a fire tube boiler?

A fire tube boiler is a type of boiler that uses hot gases generated by combustion to pass through the tubes that run through the inside of the boiler. The heat generated by the hot gases is transferred to the water surrounding the tubes, which is then converted into steam.

Fire tube boilers are commonly used for heating and providing steam for industrial applications, such as power generation, food processing, chemical processing, and building heating. They are often used in situations where a large amount of steam needs to be generated quickly, and where the demand for steam fluctuates.

One advantage of fire tube boilers is that they are relatively easy to operate and maintain, making them a popular choice for many industries. However, they are typically less efficient than other types of boilers, such as water tube boilers, and may not be suitable for high-pressure applications or where very precise temperature control is required.

Need a new boiler?

What are the four types of fire tube boilers?

The four main types of fire tube boilers are:

- Cornish Boiler: This is the simplest type of fire tube boiler, consisting of a single cylindrical shell with a large flame tube, or furnace, running through the center. The hot gases from the furnace pass through a series of tubes located at the back of the boiler, transferring their heat to the water surrounding the tubes.

- Lancashire Boiler: This type of boiler consists of two cylindrical shells connected by two large flues, with a large furnace located in the front shell. The hot gases from the furnace pass through the flues to the back of the boiler, where they then travel through a series of smaller tubes before being vented into the atmosphere.

- Scotch Boiler: This type of boiler is similar to the Lancashire boiler, but has only one cylindrical shell. The furnace is located at the bottom of the shell, with the hot gases rising up through a series of tubes before being vented to the atmosphere.

- Locomotive Boiler: This type of boiler is typically used in locomotives and other mobile applications, and is similar to the Scotch boiler. The main difference is that the furnace is located inside the cylindrical shell, with the hot gases passing through a series of tubes located at the front of the boiler before being vented to the atmosphere.

What are the 3 advantages of a fire tube boiler?

Here are three advantages of a fire tube boiler:

- Easy to operate and maintain: The fire tube design is relatively simple and easy to handle, making it a popular choice in many industries. They also have fewer parts than other types of boilers, which means they are easier to maintain and repair.

- Quick steam generation: These can generate a large amount of steam quickly, making them ideal for applications where there is a sudden and temporary demand for steam. This makes them a popular choice for power generation and industrial processes.

- Lower cost: Fire tubes are typically less expensive to install and maintain compared to other types of boilers, such as water tube boilers. They are also often more readily available, making them a convenient choice for many industries.

What is the disadvantage of fire tube boilers?

One disadvantage of fire tube boilers is that they are generally less efficient than other types of boilers, such as water tube boilers. This is because the heat transfer process in fire tube boilers is less efficient due to the relatively small size of the tubes and the large volume of water that needs to be heated. As a result, more fuel is needed to generate the same amount of steam as compared to water tube boilers. Additionally, fire tube boilers are typically limited in their maximum operating pressure, which means they may not be suitable for applications that require high-pressure steam. Finally, they are not suitable for applications where very precise temperature control is required, as they tend to have a large temperature gradient from the hottest part of the furnace to the coolest part of the boiler.

Get FREE Boiler Quotes

Get FREE Local Boiler Quotes today

Compare The Best Prices

Save Money On Your New Boiler Today!

How efficient is a fire tube?

Fire tube boilers are generally less efficient than water tube boilers due to the design of their heat transfer system. The heat transfer efficiency in fire tube boilers is limited by the relatively small size of the tubes and the large volume of water that needs to be heated. As a result, fire tube boilers typically have thermal efficiencies in the range of 70% to 80%, depending on the specific design and operating conditions. This means that for every unit of fuel input, 70% to 80% of the heat is converted to useful steam energy, while the remaining 20% to 30% is lost to the surroundings. However, the efficiency of a fire tube boiler can be improved by incorporating additional heat recoveries systems, such as economizers or air preheaters, which can capture and reuse some of the waste heat that would otherwise be lost.

Fire Tube Boiler Example

The case study involves the implementation of a fire tube boiler at a manufacturing plant that produces dairy products. The plant had previously used an aging water tube boiler that was not meeting their steam production needs and was consuming a lot of energy. The plant decided to replace the old boiler with a new fire tube boiler that was better suited to their needs.

The fire tube boiler that was installed had a thermal efficiency of 82% and a maximum operating pressure of 150 psi. The boiler was designed to provide a maximum steam output of 10,000 pounds per hour, which was sufficient to meet the plant’s steam demand.

The implementation of the fire tube boiler resulted in several benefits for the manufacturing plant, including:

Increased energy efficiency: The new fire tube boiler was more energy-efficient than the old water tube boiler, resulting in lower energy costs and reduced greenhouse gas emissions.

Improved steam production: The fire tube boiler was able to produce a higher volume of steam than the old water tube boiler, which improved the plant’s production capabilities.

Reduced maintenance requirements: The fire tube boiler was easier to maintain than the old water tube boiler, which reduced maintenance costs and downtime.

Overall, the implementation of the fire tube boiler was a success, and the manufacturing plant was able to meet its steam production needs more efficiently and effectively than before.

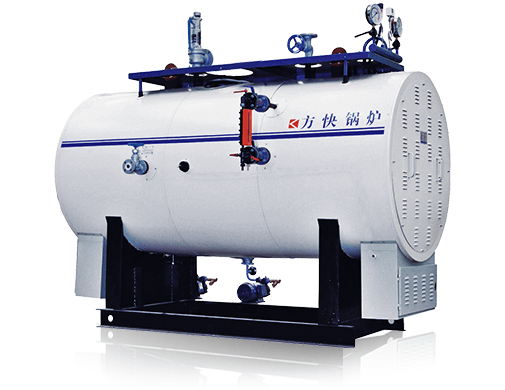

Looking for boilers with sophisticated manufacturing, great quality?

Fangkuai boiler can always provide what you want.

Conclusion

Fire tube boiler is the most common type of boiler used in industries and homes. It has been in use since the 19th century and its popularity has only increased over time because of its efficiency and durability. The most important thing to look out for when buying a fire tube boiler is its efficiency rate which should be at least 80% or more. There are many types available but our top pick would be the fired-tube boiler because it uses less fuel compared with other types while maintaining high output capacity at the same time; thus saving money on your energy bills!

If you are still not sure which type of boiler is best for your home, then we recommend that you contact us. We will be able to advise you on which type of boiler is best for your needs and provide information on its cost. WhatsApp: +86 188-3890-8339

Electric Hot Water Boiler

Electric Hot Water Boiler  Electric Steam Boiler

Electric Steam Boiler  V6 Gas Fired Hot Water Boiler

V6 Gas Fired Hot Water Boiler  2023 Gas Boiler Prices Guide | Comparing Home Gas Boiler Costs

2023 Gas Boiler Prices Guide | Comparing Home Gas Boiler Costs  Best Wood Gasification Boilers For Sale | Buying Guide

Best Wood Gasification Boilers For Sale | Buying Guide  Electric Combi Boiler Prices | 2023 Buying Guide

Electric Combi Boiler Prices | 2023 Buying Guide