How Boiler Economizers Reduce Energy Consumption

Boilers are an essential component in many industries, providing the necessary heat and power to run various processes. However, they are also significant consumers of energy, and reducing their energy consumption is an important goal for many businesses. One way to achieve this is through the use of boiler economizers.

A boiler economizer is a heat exchanger device that captures waste heat from a boiler’s exhaust gas and uses it to preheat the incoming feedwater. This helps to reduce the amount of energy required to raise the feedwater temperature to the desired level, which in turn increases the efficiency of the boiler and reduces energy consumption. Boiler economizers are typically made up of a series of tubes or pipes that are arranged in a serpentine pattern and are designed to maximize the surface area available for heat transfer. They are commonly used in various industries such as power generation, manufacturing, and food processing, among others.

How Does a Boiler Economizer Work?

A boiler economizer works by capturing waste heat from the flue gas leaving the boiler and using it to preheat the incoming feedwater. This is accomplished through a series of tubes or pipes that are arranged in a serpentine pattern inside the economizer. The feedwater is routed through these tubes, where it absorbs heat from the flue gas before it enters the boiler.

The amount of heat that can be recovered by a boiler economizer depends on a variety of factors, including the size and type of the boiler, the temperature of the flue gas leaving the boiler, and the temperature of the incoming feedwater. However, in most cases, an economizer can recover anywhere from 5% to 20% of the heat energy that would otherwise be lost in the boiler’s exhaust.

Need a new boiler?

Types of Boiler Economizers

There are several different types of boiler economizers, including:

- Non-condensing Economizers: These are the most common type of economizer and are used to recover heat from the boiler’s flue gas. They are typically installed on the stack of the boiler and are most effective when the flue gas temperature is above 300°F.

- Condensing Economizers: These economizers are designed to recover heat from the boiler’s flue gas and also from the water vapor that is produced during combustion. They are typically installed on the boiler’s hot water supply line and can be effective at temperatures as low as 130°F.

- Feedwater Economizers: These economizers are installed on the feedwater side of the boiler and are used to preheat the incoming feedwater before it enters the boiler. They can be used in conjunction with other types of economizers to achieve even greater energy savings.

Get FREE Boiler Quotes

Get FREE Local Boiler Quotes today

Compare The Best Prices

Save Money On Your New Boiler Today!

How do I choose the right economizer for my boiler?

An economizer is a device used to improve the efficiency of a boiler by capturing waste heat from the flue gas and using it to preheat the feedwater entering the boiler. Choosing the right economizer for your boiler depends on several factors, including:

- Boiler Type: The type of boiler you have, such as a fire-tube or water-tube boiler, will affect the type of economizer you can use.

- Operating Conditions: The operating conditions of your boiler, such as the temperature and pressure, will impact the type of economizer that will work best.

- Fuel Type: The type of fuel you use in your boiler will impact the selection of economizer materials and design.

- Efficiency Goals: Your desired efficiency goals will also impact the choice of economizer, as some types are more efficient than others.

- Cost and Maintenance: The cost of the economizer and the maintenance requirements should also be considered.

- Available Space: The available space for the installation of the economizer should also be taken into account, as some types of economizers require more space than others.

To choose the right economizer for your boiler, it is recommended that you consult with an experienced engineer or consultant who specializes in boiler systems. They can assess your specific needs and recommend an appropriate economizer design that will help you achieve your efficiency goals while taking into account the other factors mentioned above.

Benefits of Boiler Economizers

There are several benefits to using a boiler economizer, including:

- Increased Boiler Efficiency: By preheating the feedwater, a boiler economizer can increase the efficiency of the boiler, resulting in lower energy consumption and operating costs.

- Reduced Emissions: Since less fuel is required to heat the boiler, using an economizer can also result in reduced emissions of greenhouse gases and other pollutants.

- Increased Equipment Life: By reducing the amount of stress placed on the boiler, using an economizer can also extend the life of the boiler and reduce maintenance costs.

- Cost Savings: Depending on the size of the boiler and the amount of energy that can be recovered, using an economizer can result in significant cost savings over time.

Installation and Maintenance of Boiler Economizers

Installing a boiler economizer is a relatively straightforward process and can typically be completed in a day or two. However, it is important to ensure that the economizer is properly sized and installed to achieve maximum energy savings.

Once installed, a boiler economizer requires minimal maintenance, typically consisting of regular cleaning and inspection to ensure that the tubes or pipes are free of debris and in good working condition.

Conclusion

Boiler economizers are a simple and effective way to reduce energy consumption and increase boiler efficiency. By capturing waste heat from a boiler’s exhaust gases and using it to preheat.

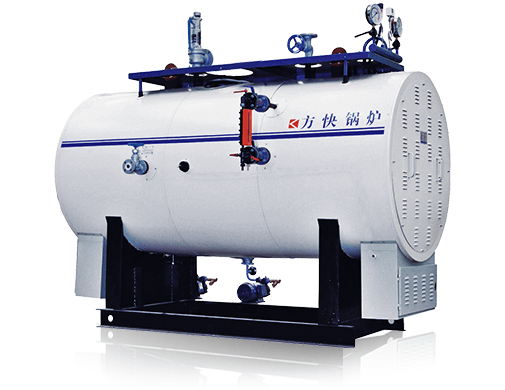

Looking for boilers with sophisticated manufacturing, great quality?

Fangkuai boiler can always provide what you want.

Electric Hot Water Boiler

Electric Hot Water Boiler  Electric Steam Boiler

Electric Steam Boiler  V6 Gas Fired Hot Water Boiler

V6 Gas Fired Hot Water Boiler  2023 Gas Boiler Prices Guide | Comparing Home Gas Boiler Costs

2023 Gas Boiler Prices Guide | Comparing Home Gas Boiler Costs  Best Wood Gasification Boilers For Sale | Buying Guide

Best Wood Gasification Boilers For Sale | Buying Guide  Electric Combi Boiler Prices | 2023 Buying Guide

Electric Combi Boiler Prices | 2023 Buying Guide