2023 Condensing Gas Boiler Price Comparison Guide

A condensing gas boiler is a type of heating system that uses natural gas or propane to generate heat for a home or commercial building. These systems are designed to be more energy efficient than traditional non-condensing gas boilers, as they are able to capture and utilize more of the heat that is produced during the combustion process.

Gas Condensing boilers work by burning natural gas or propane to generate heat, which is then used to warm the water in the boiler’s heat exchanger. The heat exchanger is a series of tubes or coils that are filled with water and surrounded by the gas flames. As the water in the heat exchanger is heated, it is circulated through the building’s heating system, such as radiators or underfloor pipes, to provide warmth.

One of the key features of a gas condensing boiler is the condensate drain, which is a pipe that is connected to the heat exchanger. As the heated water in the heat exchanger cools and becomes steam, it releases latent heat that can be captured and used to further heat the water in the heat exchanger. This process allows a condensing gas boiler to be more efficient than a non-condensing gas boiler, as it is able to capture and utilize more of the heat that is produced during the combustion process.

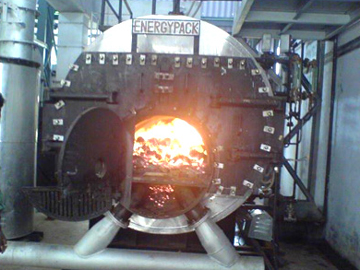

How Condensing Gas Boilers Work

high efficiency gas condensing boiler

Condensing gas boilers are a type of heating system that uses natural gas or propane to generate heat for a home or commercial building. These systems are designed to be more energy efficient than traditional non-condensing gas boilers, as they are able to capture and utilize more of the heat that is produced during the combustion process. Here is a general overview of how a gas condensing boiler works:

The burner burns natural gas or propane to generate heat.The heat is transferred to the water in the heat exchanger, which is a series of tubes or coils filled with water and surrounded by the gas flames.As the water in the heat exchanger is heated, it is circulated through the building’s heating system, such as radiators or underfloor pipes, to provide warmth.The exhaust gases from the combustion process are cooled and the latent heat is recovered and used to further heat the water in the heat exchanger.The cooled exhaust gases are then vented to the outside of the building through a flue pipe.

The key difference between a condensing and a non-condensing gas boiler is the way in which the heat produced during the combustion process is utilized. In a gas condensing boiler, the exhaust gases are cooled and the latent heat is recovered and used to further heat the water in the heat exchanger, making the system more efficient. In a non-condensing gas boiler, this heat is lost to the atmosphere.

Condensing gas boilers are generally reliable and efficient, with many models featuring advanced controls and diagnostic systems to ensure smooth operation. However, it is important to properly size and maintain a gas condensing boiler to ensure that it is operating at its maximum efficiency.

Need a new boiler?

The Benefits of Condensing Gas Boilers

Condensing gas boiler advantages

Condensing gas boilers are a popular choice for heating homes and commercial buildings due to their energy efficiency and potential cost savings. Here are some of the main benefits of these systems:

Energy efficiency: Condensing gas boilers are more efficient than traditional non-condensing gas boilers, as they are able to capture and utilize more of the heat that is produced during the combustion process. This can result in lower energy bills and a reduced carbon footprint.

Cost savings: In addition to lower energy bills, condensing gas boilers may also require less maintenance and have a longer lifespan than non-condensing gas boilers, which can result in long-term cost savings.

Improved indoor air quality: Condensing gas boilers emit fewer greenhouse gases and other pollutants during the combustion process, which can improve indoor air quality and reduce the risk of respiratory issues.

Reliability: Condensing gas boilers are generally reliable and efficient, with many models featuring advanced controls and diagnostic systems to ensure smooth operation.

It is important to note that the energy efficiency and cost savings of a condensing gas boiler will depend on a number of factors, such as the size and design of the heating system, the fuel type, and the age and condition of the boiler. Proper installation and maintenance of the system can also impact its efficiency and cost effectiveness.

Overall, condensing gas boilers offer a number of benefits for homeowners and commercial building owners looking to reduce energy costs and improve the efficiency of their heating systems.

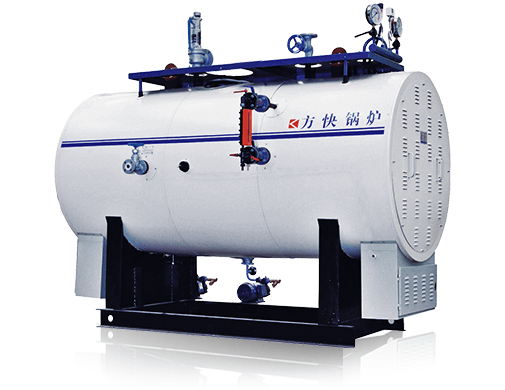

The Cost of Condensing Gas Boilers

gas condensing boiler price

The cost of a condensing gas boiler will depend on a number of factors, including the size of the unit, the fuel type, and the brand. On average, condensing gas boilers can cost anywhere from $2,000 to $10,000 or more, with larger and more advanced models tending to be on the higher end of this range.

It is important to note that the initial cost of a condensing gas boiler may be higher than a non-condensing gas boiler or other types of heating systems. However, condensing gas boilers are generally more energy efficient and may require less maintenance over time, which can result in long-term cost savings through lower energy bills and reduced repair costs.

The fuel type can also impact the cost of a condensing gas boiler. Natural gas is typically the most affordable fuel option, followed by propane, with oil being the most expensive. The cost of fuel will depend on the local market and may fluctuate over time.

The brand and reputation of the manufacturer can also influence the price of a condensing gas boiler. Higher-quality brands with a good reputation for reliability and efficiency may have a higher price tag, but may also have a longer lifespan and require less maintenance over time.

Overall, it is important to consider the long-term cost and energy efficiency of a condensing gas boiler, rather than just the initial price. While a higher-priced unit may have a higher initial cost, it may also offer greater energy efficiency and long-term cost savings. It is also a good idea to compare prices from multiple manufacturers and dealers before making a decision on a condensing gas boiler.

Get FREE Boiler Quotes

Get FREE Local Boiler Quotes today

Compare The Best Prices

Save Money On Your New Boiler Today!

Factors That Influence the Price of Condensing Gas Boilers

Condensing Gas Boilers cost

There are several factors that can influence the price of a condensing gas boiler, including:

Size of the unit: The size of the condensing gas boiler will affect its price, as larger units generally cost more than smaller ones. It is important to properly size a condensing gas boiler for the heating system and home to ensure that it is efficient and cost-effective.

Fuel type: The fuel type used by the condensing gas boiler can impact its price. Natural gas is typically the most affordable fuel option, followed by propane, with oil being the most expensive. The cost of fuel will depend on the local market and may fluctuate over time.

Location: The location of the building where the condensing gas boiler will be installed can also impact the price. Factors such as the local cost of labor and materials, as well as the availability of fuel, can affect the overall cost of the unit.

Overall, it is important to consider the size, fuel type, brand, location, and extra features when comparing the prices of different condensing gas boilers. It is also a good idea to consult with a heating professional to determine the best system for your needs and budget.

What is the difference between a condensing boiler and a combi boiler?

condensing boiler vs combi boiler

A condensing boiler and a combi boiler are two different types of heating systems that are used to heat homes and commercial buildings. While both types of systems use natural gas or propane to generate heat, there are some key differences between the two:

Heat source: A condensing boiler uses a separate heat exchanger to transfer heat from the burner to the water in the heating system. A combi boiler, on the other hand, does not have a separate heat exchanger and instead heats the water for the heating system directly in the main body of the boiler.

Hot water production: A combi boiler is designed to produce hot water on demand, while a condensing boiler may require a separate tank or cylinder to store hot water.

Efficiency: Both condensing boilers and combi boilers are generally more efficient than traditional non-condensing boilers, as they are able to capture and utilize more of the heat that is produced during the combustion process. However, condensing boilers may be slightly more efficient due to their ability to capture and utilize latent heat from the exhaust gases.

Size and installation: Combi boilers are generally smaller and more compact than condensing boilers, which can make them easier to install in tight spaces. However, the size of the unit will depend on the specific model and heating requirements of the building.

Overall, the choice between a condensing boiler and a combi boiler will depend on the specific heating needs and preferences of the homeowner or building owner. It is important to consider the size, efficiency, hot water production, and installation requirements of the two types of systems when making a decision.

Looking for boilers with sophisticated manufacturing, great quality?

Fangkuai boiler can always provide what you want.

Conclusion

In conclusion, condensing gas boilers are a type of heating system that uses natural gas or propane to generate heat for a home or commercial building. These systems are designed to be more energy efficient than traditional non-condensing gas boilers, as they are able to capture and utilize more of the heat that is produced during the combustion process. The key difference between a condensing and a non-condensing gas boiler is the way in which the heat produced during the combustion process is utilized. In a condensing gas boiler, the exhaust gases are cooled and the latent heat is recovered and used to further heat the water in the heat exchanger, making the system more efficient.

Electric Hot Water Boiler

Electric Hot Water Boiler  Electric Steam Boiler

Electric Steam Boiler  V6 Gas Fired Hot Water Boiler

V6 Gas Fired Hot Water Boiler  2023 Gas Boiler Prices Guide | Comparing Home Gas Boiler Costs

2023 Gas Boiler Prices Guide | Comparing Home Gas Boiler Costs  Best Wood Gasification Boilers For Sale | Buying Guide

Best Wood Gasification Boilers For Sale | Buying Guide  Electric Combi Boiler Prices | 2023 Buying Guide

Electric Combi Boiler Prices | 2023 Buying Guide