Einführung

High pressure steam boiler is a type of steam boiler. Es funktioniert durch Erhitzen von Wasser und Erzeugen von Dampf unter Hochdruckbedingungen. There are several types of high pressure steam boilers available in the market with different applications and features. In diesem Artikel, we will discuss all aspects related to high pressure steam boilers such as how they work, how they are different from low-pressure boilers etc…

What is a high pressure steam boiler?

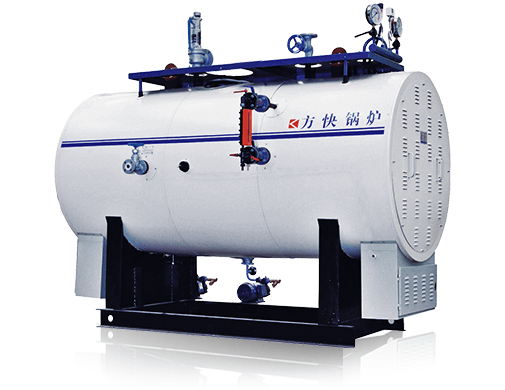

high pressure boiler for sale

A high pressure steam boiler is a type of boiler that operates at high pressure, which allows it to generate more heat than a conventional boiler. High pressure steam boilers are used in industries such as power generation and food processing.

Pressure vessels are used to contain the steam produced by the high pressure steam boilers. The pressure vessel is made of steel or other materials and can be pressurized to over 200 bar (2900 psi).

Brauche einen neuen Kessel?

How does a high pressure steam boiler work?

Working principle of high pressure boiler

The high pressure steam boiler (HPSB) generates steam by heating water. The heat from the combustion of fuel is transferred to the water in a large heat transfer unit through thermal contact. This produces a superheated fluid, d.h., one with a temperature higher than its boiling point at atmospheric pressure.

The steam generated is then used to drive a turbine that drives an electric generator or mechanical drive equipment such as pumps, compressors and fans etc.

Due to lack of space in urban areas where most power stations are located, HPSBs typically have only one stage of expansion resulting in low efficiency compared with other types such as combined cycle gas turbine plants which use multiple stages to increase efficiency.

What is the maximum pressure on a steam boiler?

High Pressure Steam Boiler Pressure

The maximum pressure of a steam boiler is typically around 25 bar. The maximum pressure depends on the design of the boiler and on the application of steam. Zum Beispiel, in some applications, where there are safety valves or other safety systems installed to protect against overpressure in case of failure, it may be possible for pressure to be higher than 25 bar.

In general terms:

the maximum pressure is the point at which the boiler is said to be superheated. This means that there is no moisture left in the steam and it has a temperature above 100°C.

What is difference between high pressure and low-pressure boiler?

high pressure boiler vs low-pressure boiler

A high pressure steam boiler is a steam boiler that operates at pressures of 80 PSIG and above. High-pressure boilers are generally used in power generation, mining, marine propulsion and heavy industry. Low-pressure boilers operating pressures up to 70 PSIG are common in industrial plants requiring heat from combustion equipment (zum Beispiel, furnaces) as well as process heating applications such as distillation towers.

High-pressure boilers tend to be more efficient than low pressure boilers because they can operate closer to their maximum theoretical efficiency.

Where are high pressure boilers used?

High Pressure Steam Boiler Application

High pressure boilers are used in the chemical industry, especially for steam sterilization, pasteurization and other processes. They are also used in food and beverage processing operations such as milk pasteurization and water purification. In addition to their use in these industries, high pressure boilers are used in pharmaceutical manufacturing facilities where sterile conditions must be maintained at all times. In pulp and paper mills high pressure boilers are used for steam generation or as a source of process steam needed for cooking chemicals before they enter the paper making process.

Holen Sie sich KOSTENLOSE Angebote für Heizkessel

Holen Sie sich noch heute KOSTENLOSE lokale Boiler-Angebote

Vergleichen Sie die besten Preise

Sparen Sie noch heute Geld bei Ihrem neuen Heizkessel!

What are the characteristics of high pressure boiler?

High pressure steam boilers are a heat exchanger system used to generate steam. They are often used in power generation and industrial processes. High pressure steam boilers can also be used for water heating and process heating, depending on their design parameters.

High pressure steam boilers have high thermal efficiency, which means that they convert fuel into energy very efficiently—around 60 percent of the fuel is converted into useful energy, compared with 30 percent for a typical coal-fired plant or 40 percent for natural gas plants (in the U.S.).

Types of High Pressure Steam Boilers

There are several types of High Pressure Steam Boilers, wie zum Beispiel: Wasserrohrkessel, Feuerrohrkessel, Waterwall Boiler and Water-Wall Tube Water Tube Steam Boiler.

- Water-tube Boilers: In this type of boiler, water flows inside the tubes and the hot gases from the combustion chamber surrounds the tubes. They are generally more efficient than fire-tube boilers and are used in large industrial settings such as power plants. These are usually two pass design, but some designs may have three pass. The large heat exchange surface area and high efficiency make this type of boiler ideal for generating large amounts of steam at high pressures.

- Fire-tube Boilers: In this type of boiler, the hot gases from the combustion chamber pass through the tubes, which are surrounded by water. They are generally less efficient than water-tube boilers and are used in smaller industrial settings, as well as in residential and commercial heating systems. Fire-tube boilers are usually smaller in size and are less expensive to purchase.

Water-tube boilers tend to be more expensive and require more skilled labor to operate and maintain, while fire-tube boilers are less expensive and can be operated by less skilled personnel. The choice of which type of boiler to use is generally determined by the size of the system, the required pressure and steam output, and the cost of the installation.

It’s also possible to find combination of these two main types of boilers, call as hybrid boilers which can take advantages of both types.

How much does it cost to install a high pressure steam boiler?

The cost of installation can vary depending on the location, size and brand of your boiler. Installing a high pressure steam boiler can cost anywhere from $5,000 zu $100,000. It’s important to note that the overall cost will be higher if you’re installing it in a remote location because this will require more time and materials.

Fazit

High pressure steam boilers are a great way to heat your home and produce hot water. They are also cost-efficient and environmentally friendly. Jedoch, there are some things you should consider before installing a high pressure system in your home. These include how much it will cost to install as well as how much energy will be used by the boiler itself when running at full capacity. Also keep in mind that high pressure boilers run on natural gas so make sure you have access to this type of fuel source before purchasing one or two units for installation purposes only!

Auf der Suche nach Kesseln mit anspruchsvoller Fertigung, großartige Qualität?

Der Fangkuai-Kessel kann immer liefern, was Sie wollen.

Elektrischer Warmwasserboiler

Elektrischer Warmwasserboiler  Elektrischer Dampfkessel

Elektrischer Dampfkessel  V6 gasbefeuerter Heißwasserboiler

V6 gasbefeuerter Heißwasserboiler  2023 Preisführer für Gaskessel | Vergleich der Kosten für Gaskessel zu Hause

2023 Preisführer für Gaskessel | Vergleich der Kosten für Gaskessel zu Hause  Die besten Holzvergaserkessel zum Verkauf | Einkaufsführer

Die besten Holzvergaserkessel zum Verkauf | Einkaufsführer  Preise für elektrische Kombikessel | 2023 Einkaufsführer

Preise für elektrische Kombikessel | 2023 Einkaufsführer