Die Kraft der Abwärme nutzen: Ein umfassender Leitfaden für Abhitzekessel

Waste heat is a byproduct of industrial processes that is often overlooked as a source of energy. The energy generated from this waste heat can be captured and utilized to power other processes, making it a valuable resource for industries. In diesem Artikel, we will explore the concept of waste heat and its utilization in the form of waste heat boilers.

What is Waste Heat Boiler?

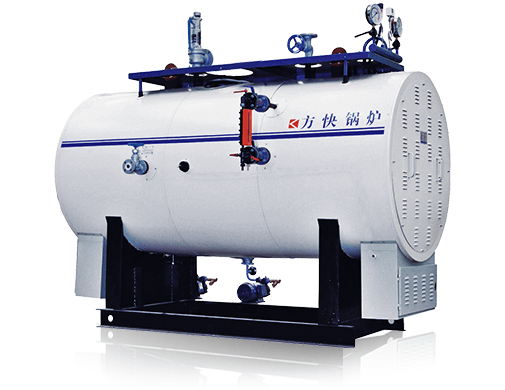

A waste heat boiler is a type of boiler that utilizes the heat generated as a byproduct of industrial processes to produce steam or heißes Wasser. The heat source can come from various industrial processes such as furnaces, engines, turbines, incinerators, and so on, which would otherwise be released into the atmosphere. The waste heat is collected and transferred to a heat exchanger, where it is used to generate steam or hot water for various purposes such as heating, Energieerzeugung, and process applications.

Waste heat boilers are designed to operate at high temperatures and are typically made from materials that can withstand high levels of thermal stress and corrosion. They play an important role in improving the energy efficiency of industrial processes, as they recover and reuse energy that would otherwise be lost to the environment.

Sichern Sie sich einen Online-Festpreis 20 Sekunden:

What is Waste Heat?

Waste heat refers to the heat energy that is generated as a byproduct of an industrial process and is not used for any specific purpose. This energy is often discharged into the environment, leading to an increased carbon footprint and increased energy costs. The temperature of waste heat can vary depending on the process, but it is usually in the range of 50°C to 450°C.

Why is Waste Heat Recovery Important?

Waste heat recovery is becoming increasingly important as industries look for ways to reduce their carbon footprint and save on energy costs. By capturing and utilizing waste heat, industries can reduce their reliance on fossil fuels, which are a finite resource and contribute to global warming. Zusätzlich, waste heat recovery can improve the overall efficiency of industrial processes, as the recovered heat energy can be used to power other processes.

How do Waste Heat Boilers Work?

Waste heat boilers are designed to capture and utilize waste heat from industrial processes. They work by absorbing the heat energy from the waste heat source, such as a furnace flue gas, and using it to generate steam. This steam can then be used to power a turbine, which generates electricity. Das electricity generated from the waste heat can be used on-site or sold back to the grid.

Brauche einen neuen Kessel?

Types of Waste Heat Boilers:

There are several types of waste heat boilers, each designed to handle a specific type of waste heat source. Some of the most common types of boilers include:

- Furnace Waste Heat Boilers: These boilers are designed to capture waste heat from furnaces, such as those used in the steel, aluminum, and glass industries.

- Process Gas Waste Heat Boilers: These boilers are designed to capture waste heat from process gases, such as those generated in chemical and petrochemical industries.

- Exhaust Gas Waste Heat Boilers: These boilers are designed to capture waste heat from exhaust gases, such as those generated in internal combustion engines.

Advantages of Waste Heat Boilers:

There are several advantages of waste heat boilers, einschließlich:

- Energieeffizienz: Waste heat boilers can improve the overall energy efficiency of industrial processes, as the recovered heat energy can be used to power other processes.

- Cost Savings: By capturing and utilizing waste heat, industries can reduce their reliance on fossil fuels and save on energy costs.

- Environmental Benefits: Waste heat recovery can reduce the carbon footprint of industries and help to mitigate the impacts of global warming.

What is the efficiency of waste heat boiler?

The efficiency of a waste heat boiler depends on a number of factors, including the temperature of the waste heat source, the desired temperature of the recovered heat, and the design and size of the boiler.

Typisch, the Effizienz of a waste heat boiler can range from 50% zu 80%. The higher the temperature of the waste heat source and the lower the desired temperature of the recovered heat, the higher the efficiency of the waste heat boiler will be.

Zum Beispiel, a waste heat boiler that is recovering heat from a high-temperature process, such as a furnace or kiln, may have an efficiency of 70% or higher, while a waste heat boiler that is recovering heat from a lower-temperature process, such as a diesel engine or steam turbine, may have an efficiency in the range of 50% zu 60%.

It’s important to note that the efficiency of a waste heat boiler can also be influenced by factors such as the size and design of the boiler, the quality of the insulation and heat exchangers, and the operating conditions and maintenance practices. To maximize efficiency, it’s important to select a waste heat boiler that is well-suited to your specific application and to follow good operating and maintenance practices.

Holen Sie sich KOSTENLOSE Angebote für Heizkessel

Holen Sie sich noch heute KOSTENLOSE lokale Boiler-Angebote

Vergleichen Sie die besten Preise

Sparen Sie noch heute Geld bei Ihrem neuen Heizkessel!

How Much Waste Heat Boiler Cost?

The cost of a waste heat boiler can vary widely depending on several factors such as size and capacity, material of construction, and the specific application it is being used for. Im Durchschnitt, prices for a waste heat boiler can range from a few thousand dollars to several hundred thousand dollars or more.

Smaller waste heat boilers for applications such as small-scale industrial processes or commercial heating systems may cost in the range of tens of thousands of dollars, while larger waste heat boilers used in power generation or heavy industrial processes can cost several million dollars.

It is important to note that the cost of a waste heat boiler also includes installation and any necessary auxiliary equipment, such as heat exchangers or control systems. The overall cost can also be influenced by local labor and material costs.

To get a more accurate estimate for your specific needs, I would suggest contacting a vendor or supplier who specializes in waste heat boilers and providing them with details about your requirements.

Fazit

Waste heat is a valuable resource that is often overlooked in industrial processes. By utilizing waste heat boilers, industries can reduce their reliance on fossil fuels, save on energy costs, and reduce their carbon footprint. Whether you’re looking to improve the efficiency of your industrial processes or reduce your environmental impact, waste heat boilers are a smart investment.

Auf der Suche nach Kesseln mit anspruchsvoller Fertigung, großartige Qualität?

Der Fangkuai-Kessel kann immer liefern, was Sie wollen.

Elektrischer Warmwasserboiler

Elektrischer Warmwasserboiler  Elektrischer Dampfkessel

Elektrischer Dampfkessel  V6 gasbefeuerter Heißwasserboiler

V6 gasbefeuerter Heißwasserboiler  2023 Preisführer für Gaskessel | Vergleich der Kosten für Gaskessel zu Hause

2023 Preisführer für Gaskessel | Vergleich der Kosten für Gaskessel zu Hause  Die besten Holzvergaserkessel zum Verkauf | Einkaufsführer

Die besten Holzvergaserkessel zum Verkauf | Einkaufsführer  Preise für elektrische Kombikessel | 2023 Einkaufsführer

Preise für elektrische Kombikessel | 2023 Einkaufsführer