Wasserrohrkessel vs. Feuerrohrkessel: Welches ist das Richtige für Sie?

Heizkessel sind ein wesentlicher Bestandteil vieler industrieller und gewerblicher Betriebe, providing the energy needed to power machinery and heat buildings. When it comes to selecting the right type of boiler for your needs, jedoch, there are two main options to choose from: water tube boilers und fire tube boilers. In diesem Artikel, we’ll explore the differences between these two types of boilers and help you decide which one is right for your application.

Brauche einen neuen Kessel?

What is the difference between a water tube boiler and a fire tube boiler?

Water tube boilers and fire tube boilers are two common types of boilers used in many industries. The main difference between the two is the way they generate and distribute hot gases and water.

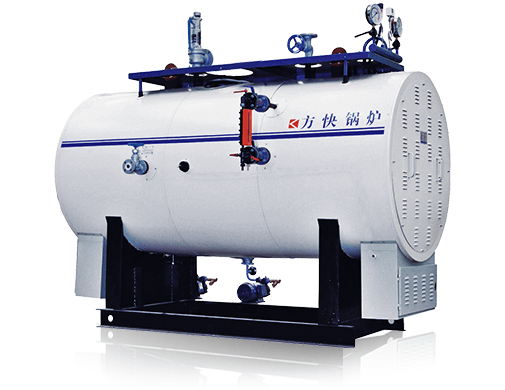

In a Feuerrohrkessel, the hot gases produced by the combustion of fuel pass through a series of tubes that are immersed in water. The heat from the gases is transferred to the water through the walls of the tubes, which generates steam. The steam is collected in a drum and used for various applications. Fire tube boilers are typically used in smaller applications and are simpler in design.

In a water tube boiler, water flows through a network of tubes that are heated by hot gases produced by the combustion of fuel. The hot gases pass over the outside of the tubes, heating the water inside. Water tube boilers are typically used in larger applications, wie etwa die Stromerzeugung, and are more complex in design.

One advantage of water tube boilers is that they can produce steam at much higher pressures than fire tube boilers, making them more efficient for power generation. Zusätzlich, because the water is contained within the tubes, water tube boilers are less susceptible to explosions than fire tube boilers, which can be dangerous in certain applications.

Gesamt, the choice of boiler type depends on the specific requirements of the application and factors such as efficiency, Sicherheit, and cost.

Which type of boiler is more efficient, a water tube or fire tube boiler?

Both water tube and fire tube boilers can be designed to be highly efficient, and the efficiency of a boiler depends on many factors, including its design, Größe, operating conditions, and the type of fuel used.

Jedoch, in general, water tube boilers are more efficient than fire tube boilers. Water tube boilers can achieve higher operating pressures and temperatures, which means they can produce steam at higher efficiencies. Water tube boilers also typically have a larger surface area for heat transfer, which can increase their overall efficiency.

Zusätzlich, water tube boilers can be designed to recover heat from the exhaust gases, further increasing their efficiency. By contrast, fire tube boilers are typically limited in their ability to recover heat from the exhaust gases.

That being said, the choice of boiler type ultimately depends on the specific requirements of the application and factors such as safety, cost, and ease of maintenance. Both water tube and fire tube boilers have their advantages and disadvantages, and the best choice depends on the specific circumstances of the application.

Sichern Sie sich einen Online-Festpreis 20 Sekunden:

What are the advantages and disadvantages of a water tube boiler compared to a fire tube boiler?

Water tube boilers offer several advantages over fire tube boilers. They are generally more efficient, more durable, and can operate at higher pressures and temperatures. Jedoch, water tube boilers are typically more expensive to purchase and install. They also require more maintenance and can be more difficult to repair if something goes wrong.

Fire tube boilers, auf der anderen Seite, are generally less expensive to purchase and install. They are also simpler in design, which makes them easier to repair if something goes wrong. Jedoch, fire tube boilers are generally less effizient than water tube boilers and may not be suitable for high-pressure applications.

Which type of boiler is more commonly used in industrial settings?

Both water tube and fire tube boilers are used in industrial settings, but the specific choice of boiler type depends on many factors, including the size and capacity of the application, die Art des verwendeten Kraftstoffs, the required steam pressure and temperature, and the level of efficiency required.

Water tube boilers are typically used in larger industrielle Anwendungen, wie etwa die Stromerzeugung, chemische Verarbeitung, and oil refining. These applications often require high-pressure steam and can benefit from the efficiency and safety advantages of water tube boilers.

Fire tube boilers are commonly used in smaller industrial applications, such as heating and process applications in commercial and institutional settings. They are simpler in design and easier to maintain, which can make them more cost-effective for smaller applications.

Ultimately, the choice of boiler type depends on the specific requirements of the application, and a qualified engineer or technician should be consulted to help determine the best boiler type and configuration for a given application.

Fazit

Abschließend, water tube and fire tube boilers are two common types of boilers used in many industrial applications. Water tube boilers are typically used in larger applications that require high-pressure steam and can benefit from the efficiency and safety advantages of this type of boiler. Fire tube boilers are commonly used in smaller applications and are simpler in design and easier to maintain, which can make them more cost-effective for smaller applications.

Jedoch, the specific choice of boiler type depends on many factors, including the size and capacity of the application, die Art des verwendeten Kraftstoffs, and the required steam pressure and temperature, and a qualified engineer or technician should be consulted to determine the best boiler type and configuration for a given application.

To learn more about water tube boilers, please contact our engineers at +86 188-3890-8339 oder find a representative in your area.

Elektrischer Warmwasserboiler

Elektrischer Warmwasserboiler  Elektrischer Dampfkessel

Elektrischer Dampfkessel  V6 gasbefeuerter Heißwasserboiler

V6 gasbefeuerter Heißwasserboiler  2023 Preisführer für Gaskessel | Vergleich der Kosten für Gaskessel zu Hause

2023 Preisführer für Gaskessel | Vergleich der Kosten für Gaskessel zu Hause  Die besten Holzvergaserkessel zum Verkauf | Einkaufsführer

Die besten Holzvergaserkessel zum Verkauf | Einkaufsführer  Preise für elektrische Kombikessel | 2023 Einkaufsführer

Preise für elektrische Kombikessel | 2023 Einkaufsführer