¿Qué es un horno de cartón ondulado??

A corrugated furnace is a type of furnace used in boilers and pressure vessels. It is a cylindrical chamber with a series of corrugations or ridges on the inner surface. The ridges increase the surface area of the furnace, which helps to improve heat transfer and increase efficiency.

The corrugations also help to strengthen the furnace and reduce the risk of deformation or collapse under high pressure or temperature. They allow the furnace to expand and contract without losing its shape, making it a reliable and durable component of the boiler or pressure vessel.

Corrugated furnaces are commonly used in calderas pirotubulares, which are used in many industrial processes and power generation facilities. They can also be found in some water tube boilers, which are used in large-scale applications such as power plants and petrochemical facilities.

Necesito una nueva caldera?

How does a Corrugated Furnace work?

A corrugated furnace works by providing a larger surface area for heat exchange and improving the structural integrity of the furnace. When fuel is burned in a boiler or pressure vessel, the heat produced is transferred to the water or other fluid in the vessel. This heat transfer occurs primarily through the walls of the furnace.

The corrugations in the furnace increase the surface area of the walls, allowing for more efficient heat transfer. This is because the corrugations increase the amount of contact between the hot gases inside the furnace and the walls of the furnace. Como resultado, more heat is transferred from the hot gases to the walls, and then to the water or other fluid in the vessel.

In addition to improving heat transfer, the corrugations also help to strengthen the furnace. When the furnace is subjected to high pressure or temperature, the corrugations allow it to expand and contract without losing its shape or integrity. This reduces the risk of deformation or collapse and ensures the safe and efficient operation of the boiler or pressure vessel.

General, the corrugated furnace is a critical component of many boilers and pressure vessels, helping to improve heat transfer efficiency and maintain the structural integrity of the equipment.

What are the advantages of Corrugated Furnaces?

Corrugated furnaces are commonly used in boilers and other heating systems. They have several advantages over traditional flat furnaces, incluido:

- Increased heat transfer: The corrugations increase the surface area of the furnace, which enhances heat transfer and improves the efficiency of the heating system.

- Reduced stress: The corrugations help distribute the stress caused by temperature changes evenly, reducing the risk of thermal stress cracks.

- Improved durability: The increased surface area and reduced stress make corrugated furnaces more durable and longer-lasting than traditional flat furnaces.

- Menor mantenimiento: Less prone to the accumulation of soot and other forms of dirt, reducing the need for maintenance and cleaning.

- Compact design:Can be made smaller than a traditional griddle while still maintaining the same heating capacity, making it ideal for applications with limited space.

General, the advantages of corrugated furnaces make them a popular choice for many heating applications, especially in boilers and other high-temperature systems.

Obtenga cotizaciones de calderas GRATIS

Obtenga cotizaciones de calderas locales GRATIS hoy

Compara Los Mejores Precios

Ahorre dinero en su nueva caldera hoy!

What types of boilers use Corrugated Furnaces?

Corrugated furnaces can be used in a variety of boiler types, incluido:

- Fire-tube boilers: These are commonly used in fire-tube boilers, which are characterized by their cylindrical shape and the use of flue gases to heat the water or steam.

- Water-tube boilers: These can also be used in water-tube boilers, which use a network of tubes filled with water to produce steam.

- Industrial boilers: These are commonly used in industrial boilers, which are used for a variety of applications such as power generation, procesamiento químico, and heating.

- Marine boilers: These are also used in marine boilers, which are designed for use in ships and other marine vessels.

General, corrugated furnaces are versatile and can be used in a range of boiler types, making them a popular choice in many different industries and applications.

What maintenance is required for a Corrugated Furnace?

While corrugated furnaces are generally low-maintenance, they still require periodic cleaning and inspection to ensure optimal performance and prevent issues such as corrosion, fouling, and cracks. Here are some maintenance tasks that may be required for a corrugated furnace:

- Regular cleaning: Corrugated furnaces should be cleaned periodically to remove any soot, ash, or other debris that may accumulate on the surfaces. This can be done using a brush or other limpieza tool.

- Inspection for cracks and corrosion: The corrugated furnace should be inspected regularly for any signs of cracks or corrosion, which can be caused by thermal stress or chemical reactions. Any issues should be addressed promptly to prevent further damage.

- Lubrication: If the furnace has moving parts such as dampers or doors, these should be lubricated periodically to ensure smooth operation.

- Control of water quality: In boilers with corrugated furnaces, the water used for steam generation should be of good quality, with minimal impurities or corrosive elements. Water treatment systems may be required to maintain water quality.

- Monitoring of combustion: The combustion process in the furnace should be monitored regularly to ensure that it is operating efficiently and cleanly. Any issues such as incomplete combustion or excess emissions should be addressed promptly.

General, proper maintenance of a corrugated furnace is important for ensuring optimal performance and minimizing the risk of issues or downtime.

How long does a Corrugated Furnace last?

The lifespan of a corrugated furnace can vary depending on factors such as the quality of the materials, the operating conditions, and the maintenance schedule. En general, a well-maintained corrugated furnace can last for several years or even decades. Some factors that can impact the lifespan of a corrugated furnace include:

- Quality of materials: Corrugated furnaces made from high-quality materials such as stainless steel or alloy can last longer than those made from lower-grade materials.

- Operating conditions: The temperature, presión, and other operating conditions can impact the lifespan of a corrugated furnace. Por ejemplo, if the furnace is operated at high temperatures for long periods, it may be more prone to thermal stress and cracking.

- Mantenimiento: Regular maintenance and cleaning can help extend the lifespan of a corrugated furnace by reducing the risk of corrosion, fouling, and other issues.

- Water quality: If the furnace is used in a boiler, the quality of the water used for steam generation can impact the lifespan of the furnace. Corrosive or impure water can accelerate the degradation of the furnace materials.

En general, a well-maintained corrugated furnace can last for 10-20 years or more, but it is important to monitor the furnace regularly for signs of wear or damage and replace it as needed to ensure safe and efficient operation.

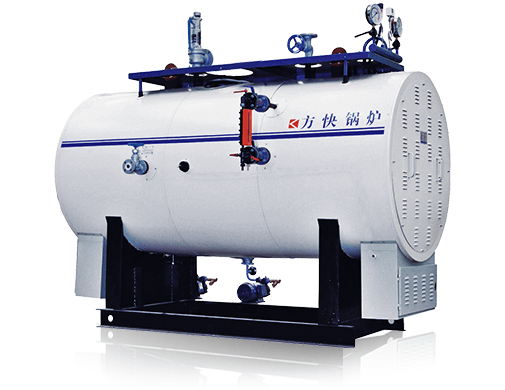

Buscando calderas con fabricación sofisticada, gran calidad?

La caldera Fangkuai siempre puede proporcionar lo que desea.

Conclusión

Corrugated Furnace is a popular choice for improving the efficiency and performance of boilers. By understanding its advantages, operation, and maintenance requirements, you can make an informed decision about whether it’s the right choice for your boiler. If you have further questions or concerns, be sure to consult with a qualified boiler technician or engineer.

Caldera de agua caliente eléctrica

Caldera de agua caliente eléctrica  Caldera de vapor eléctrica

Caldera de vapor eléctrica  Caldera de agua caliente a gas V6

Caldera de agua caliente a gas V6  2023 Guía de precios de calderas de gas | Comparación de los costos de las calderas de gas domésticas

2023 Guía de precios de calderas de gas | Comparación de los costos de las calderas de gas domésticas  Las mejores calderas de gasificación de madera a la venta | Guía de compra

Las mejores calderas de gasificación de madera a la venta | Guía de compra  Precios de calderas mixtas eléctricas | 2023 Guía de compra

Precios de calderas mixtas eléctricas | 2023 Guía de compra