Introducción

Caldera de vapor de alta presión es un tipo de caldera de vapor. Funciona calentando agua y generando vapor en condiciones de alta presión.. Hay varios tipos de calderas de vapor de alta presión disponibles en el mercado con diferentes aplicaciones y características. En este articulo, discutiremos todos los aspectos relacionados con las calderas de vapor de alta presión, como su funcionamiento, en qué se diferencian de las calderas de baja presión, etc.

¿Qué es una caldera de vapor de alta presión??

Vendo caldera de alta presion

A high pressure steam boiler is a type of boiler that operates at high pressure, which allows it to generate more heat than a conventional boiler. High pressure steam boilers are used in industries such as power generation and food processing.

Pressure vessels are used to contain the steam produced by the high pressure steam boilers. The pressure vessel is made of steel or other materials and can be pressurized to over 200 bar (2900 psi).

Necesito una nueva caldera?

How does a high pressure steam boiler work?

Working principle of high pressure boiler

La caldera de vapor de alta presión (HPSB) genera vapor calentando agua. El calor de la combustión del combustible se transfiere al agua en una gran unidad de transferencia de calor a través del contacto térmico.. Esto produce un fluido sobrecalentado., es decir., uno con una temperatura superior a su punto de ebullición a presión atmosférica.

Luego, el vapor generado se utiliza para impulsar una turbina que impulsa un generador eléctrico o un equipo de accionamiento mecánico, como bombas., compresores y ventiladores, etc..

Due to lack of space in urban areas where most power stations are located, HPSBs typically have only one stage of expansion resulting in low efficiency compared with other types such as combined cycle gas turbine plants which use multiple stages to increase efficiency.

What is the maximum pressure on a steam boiler?

High Pressure Steam Boiler Pressure

The maximum pressure of a steam boiler is typically around 25 bar. The maximum pressure depends on the design of the boiler and on the application of steam. Por ejemplo, in some applications, where there are safety valves or other safety systems installed to protect against overpressure in case of failure, it may be possible for pressure to be higher than 25 bar.

In general terms:

the maximum pressure is the point at which the boiler is said to be superheated. This means that there is no moisture left in the steam and it has a temperature above 100°C.

What is difference between high pressure and low-pressure boiler?

high pressure boiler vs low-pressure boiler

A high pressure steam boiler is a steam boiler that operates at pressures of 80 PSIG and above. High-pressure boilers are generally used in power generation, mining, marine propulsion and heavy industry. Low-pressure boilers operating pressures up to 70 PSIG are common in industrial plants requiring heat from combustion equipment (por ejemplo, furnaces) as well as process heating applications such as distillation towers.

High-pressure boilers tend to be more efficient than low pressure boilers because they can operate closer to their maximum theoretical efficiency.

Where are high pressure boilers used?

High Pressure Steam Boiler Application

High pressure boilers are used in the chemical industry, especially for steam sterilization, pasteurization and other processes. They are also used in food and beverage processing operations such as milk pasteurization and water purification. In addition to their use in these industries, high pressure boilers are used in pharmaceutical manufacturing facilities where sterile conditions must be maintained at all times. In pulp and paper mills high pressure boilers are used for steam generation or as a source of process steam needed for cooking chemicals before they enter the paper making process.

Obtenga cotizaciones de calderas GRATIS

Obtenga cotizaciones de calderas locales GRATIS hoy

Compara Los Mejores Precios

Ahorre dinero en su nueva caldera hoy!

What are the characteristics of high pressure boiler?

High pressure steam boilers are a heat exchanger system used to generate steam. They are often used in power generation and industrial processes. High pressure steam boilers can also be used for water heating and process heating, depending on their design parameters.

High pressure steam boilers have high thermal efficiency, which means that they convert fuel into energy very efficiently—around 60 percent of the fuel is converted into useful energy, compared with 30 percent for a typical coal-fired plant or 40 percent for natural gas plants (in the U.S.).

Types of High Pressure Steam Boilers

There are several types of High Pressure Steam Boilers, como: Caldera de tubo de agua, Caldera Pirotubular, Waterwall Boiler and Water-Wall Tube Water Tube Steam Boiler.

- Calderas acuotubulares: In this type of boiler, water flows inside the tubes and the hot gases from the combustion chamber surrounds the tubes. They are generally more efficient than fire-tube boilers and are used in large industrial settings such as power plants. These are usually two pass design, but some designs may have three pass. The large heat exchange surface area and high efficiency make this type of boiler ideal for generating large amounts of steam at high pressures.

- Fire-tube Boilers: In this type of boiler, the hot gases from the combustion chamber pass through the tubes, which are surrounded by water. They are generally less efficient than water-tube boilers and are used in smaller industrial settings, as well as in residential and commercial heating systems. Fire-tube boilers are usually smaller in size and are less expensive to purchase.

Water-tube boilers tend to be more expensive and require more skilled labor to operate and maintain, while fire-tube boilers are less expensive and can be operated by less skilled personnel. The choice of which type of boiler to use is generally determined by the size of the system, the required pressure and steam output, and the cost of the installation.

It’s also possible to find combination of these two main types of boilers, call as hybrid boilers which can take advantages of both types.

How much does it cost to install a high pressure steam boiler?

The cost of installation can vary depending on the location, size and brand of your boiler. Installing a high pressure steam boiler can cost anywhere from $5,000 a $100,000. It’s important to note that the overall cost will be higher if you’re installing it in a remote location because this will require more time and materials.

Conclusión

High pressure steam boilers are a great way to heat your home and produce hot water. They are also cost-efficient and environmentally friendly. Sin embargo, there are some things you should consider before installing a high pressure system in your home. Estos incluyen cuánto costará la instalación y cuánta energía utilizará la caldera cuando funcione a plena capacidad.. También tenga en cuenta que las calderas de alta presión funcionan con gas natural, así que asegúrese de tener acceso a este tipo de fuente de combustible antes de comprar una o dos unidades solo para fines de instalación.!

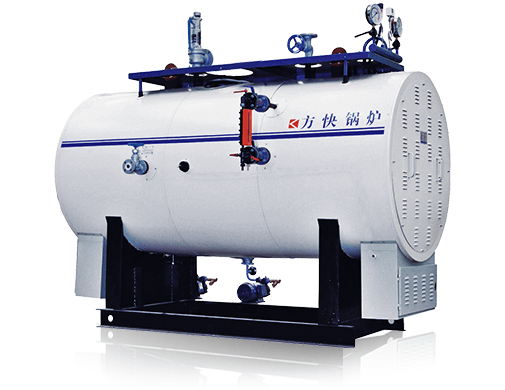

Buscando calderas con fabricación sofisticada, gran calidad?

La caldera Fangkuai siempre puede proporcionar lo que desea.

Caldera de agua caliente eléctrica

Caldera de agua caliente eléctrica  Caldera de vapor eléctrica

Caldera de vapor eléctrica  Caldera de agua caliente a gas V6

Caldera de agua caliente a gas V6  2023 Guía de precios de calderas de gas | Comparación de los costos de las calderas de gas domésticas

2023 Guía de precios de calderas de gas | Comparación de los costos de las calderas de gas domésticas  Las mejores calderas de gasificación de madera a la venta | Guía de compra

Las mejores calderas de gasificación de madera a la venta | Guía de compra  Precios de calderas mixtas eléctricas | 2023 Guía de compra

Precios de calderas mixtas eléctricas | 2023 Guía de compra