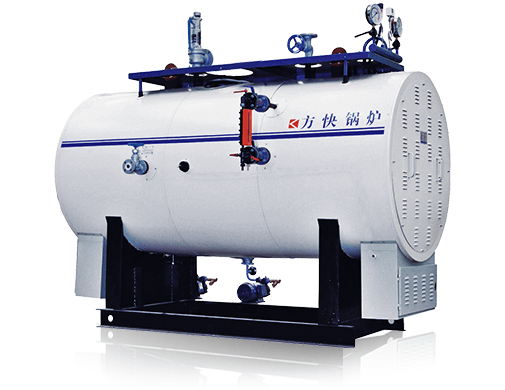

Gas(oil) Fired Water Tube Steam Boiler The boiler adopts a double-drum longitudinal “D” type arrangement structure; water, steam or steam-water mixture flows in the pipe; flame burns and flue gas flows outside the pipe, forming extremely fast steam-water flow rate and excellent water circulation system. Boiler heat absorption rate and thermal efficiency are high.

Rated thermal power: ≥10t/h

Rated thermal efficiency: 100-104%

Pressure: ≤2.5MPa

Available fuel: diesel, heavy oil, natural gas, city gas, liquefied petroleum gas, etc.

Advantages of Gas(oil) Fired Water Tube Steam Boiler

- The boiler quality is goodMore than 95% of automatic welding equipment is used. Each boiler is tested and quenched before leaving the factory. The qualified rate of inspection is 100%.

- Efficient heat transferThe drum is not directly heated, and the tube containing the water vapor is placed in the furnace and the flue as a heating surface to improve heat transfer efficiency.

- Meet large evaporation requirementsThe furnace is placed outside the cylinder, and the volume of the furnace can be large or small to meet the requirements of combustion and large evaporation.

- Small impact of the disasterThe special water pipe arrangement increases the heating surface, but the amount of boiler water is not much. In the event of a disaster, the degree of damage is small.

Gas(oil) Fired Water Tube Steam Boilers are an innovative and reliable solution for producing steam in industrial settings. They are commonly used in power generation plants, chemical processing facilities, and refineries, among others. With their high efficiency, safety features, and versatility, gas(oil) fired water tube steam boilers have become a popular choice for many industries.

If you’re considering investing in a gas(oil) fired water tube steam boiler, this article will provide you with a comprehensive overview of their features, benefits, and applications.

The Components of a Gas(oil) Fired Water Tube Steam Boiler

Burner: The burner is responsible for supplying fuel to the combustion chamber, where it is ignited and produces heat. Gas(oil) fired water tube steam boilers can use natural gas, propane, diesel, or other fuels, depending on the application.

Heat Exchanger: The heat exchanger transfers heat from the combustion gases to the water. Gas(oil) fired water tube steam boilers use a series of tubes that are surrounded by hot gases, which heat the water inside the tubes.

Water Tank: The water tank stores the water that will be heated and transformed into steam. It is important to maintain the water level within the tank to prevent damage to the boiler.

Steam Drum: The steam drum is where the steam is collected and distributed to the rest of the system.

The Steam Generation Process

The steam generation process begins with the burner igniting the fuel and producing heat. The hot gases produced by the burner flow through the heat exchanger, where they transfer their heat to the water inside the tubes. As the water absorbs the heat, it begins to boil and produce steam. The steam rises and enters the steam drum, where it is collected and distributed to the rest of the system.

Advantages of Gas(oil) Fired Water Tube Steam Boilers

Energy Efficiency

Gas(oil) fired water tube steam boilers are known for their high energy efficiency. They use less fuel to produce the same amount of steam as traditional boilers, which translates into lower operating costs and reduced carbon emissions. Additionally, gas(oil) fired water tube steam boilers are designed to recover heat from the combustion gases, further improving their efficiency.

Durability and Longevity

Gas(oil) fired water tube steam boilers are built to withstand harsh industrial environments. They are made of high-quality materials that can withstand extreme temperatures, pressure, and corrosive substances. Moreover, gas(oil) fired water tube steam boilers have fewer moving parts than traditional boilers, reducing the risk of mechanical failure and prolonging their lifespan.

Low Maintenance

Gas(oil) fired water tube steam boilers require less maintenance than other types of boilers. They have fewer components that need to be checked or replaced, which reduces downtime and maintenance costs. Additionally, gas(oil) fired water tube steam boilers are equipped with safety features that prevent them from overheating or malfunctioning, further reducing the need for maintenance.

Applications of Gas(oil) Fired Water Tube Steam Boilers

Power Generation Plants

Gas(oil) fired water tube steam boilers are commonly used in power generation plants to produce steam that drives turbines and generates electricity. They are preferred over other types of boilers due to their high efficiency and low emissions.

Chemical Processing Facilities

Gas(oil) fired water tube steam boilers are also used in chemical processing facilities to produce steam for various processes, such as heating, distillation, and sterilization. They are ideal for these applications due to their high energy efficiency and durability.

Refineries

Gas(oil) fired water tube steam boilers are widely used in refineries to produce steam that is used in various processes, such as crude oil distillation, hydrogen production, and wastewater treatment. They are preferred over other types of boilers due to their reliability, energy efficiency, and low emissions.

Food and Beverage Industry

Gas(oil) fired water tube steam boilers are also used in the food and beverage industry to sterilize equipment, cook food, and pasteurize beverages. They are preferred over other types of boilers due to their high energy efficiency, low emissions, and compliance with food safety regulations.

FAQs about Gas(oil) Fired Water Tube Steam Boilers

Q: Are gas(oil) fired water tube steam boilers more expensive than traditional boilers?

A: Gas(oil) fired water tube steam boilers may have a higher upfront cost than traditional boilers, but their high energy efficiency and low maintenance requirements make them a cost-effective solution in the long run.

Q: Can gas(oil) fired water tube steam boilers use renewable fuels?

A: Yes, gas(oil) fired water tube steam boilers can be adapted to use renewable fuels such as biomass, biogas, and hydrogen, depending on the application.

Q: What safety features do gas(oil) fired water tube steam boilers have?

A: Gas(oil) fired water tube steam boilers are equipped with safety features such as pressure relief valves, water level sensors, and flame failure protection systems to prevent them from overheating or malfunctioning.

Conclusion

Gas(oil) fired water tube steam boilers are an innovative and reliable solution for producing steam in industrial settings. They are preferred over traditional boilers due to their high energy efficiency, durability, and low emissions. Gas(oil) fired water tube steam boilers are widely used in power generation plants, chemical processing facilities, refineries, and the food and beverage industry, among others. If you’re considering investing in a gas(oil) fired water tube steam boiler, make sure to choose a reputable manufacturer and consult with a professional to ensure that you select the right boiler for your specific needs.

Electric Hot Water Boiler

Electric Hot Water Boiler  Electric Steam Boiler

Electric Steam Boiler  V6 Gas Fired Hot Water Boiler

V6 Gas Fired Hot Water Boiler  2023 Gas Boiler Prices Guide | Comparing Home Gas Boiler Costs

2023 Gas Boiler Prices Guide | Comparing Home Gas Boiler Costs  Best Wood Gasification Boilers For Sale | Buying Guide

Best Wood Gasification Boilers For Sale | Buying Guide  Electric Combi Boiler Prices | 2023 Buying Guide

Electric Combi Boiler Prices | 2023 Buying Guide