Caldaie a scambiatore di calore: The Heart of Heating Systems

Heat exchanger boilers have become increasingly popular in the last few years, especially in commercial and industrial applications. These boilers provide a cost-effective and efficient way to heat large buildings, as well as transfer heat between different fluid streams. In questo articolo, we will discuss heat exchanger boilers in detail, including their design, types, and applications.

What is a Heat Exchanger Boiler?

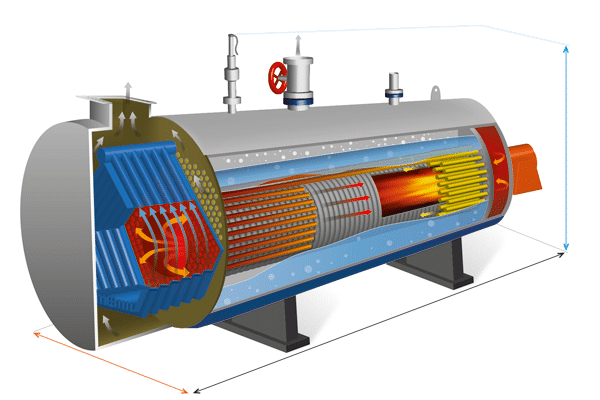

heat exchanger boiler system

A heat exchanger boiler is a type of sistema di riscaldamento that uses a heat exchanger to transfer heat from one fluid to another. This type of boiler uses two separate fluid streams, one of which is the heating medium and the other is the fluid to be heated. The heat exchanger transfers heat from the heating medium to the fluid, thus raising its temperature.

Heat exchanger boilers are designed for a variety of applications, including space heating, domestic hot water heating, and process heating. They can also be used for heat recovery, which involves capturing heat from an industrial process or other energy source and using it to preheat incoming fluid streams.

Ottieni un prezzo fisso online in 20 secondi:

Types of Heat Exchanger Boilers

- Plate Heat Exchanger Boilers

Plate heat exchanger boilers use thin metal plates to transfer heat between fluid streams. The fluid streams flow between the plates, which are separated by a small gap. The heat is transferred from one fluid stream to the other through the metal plates.

- Shell and Tube Heat Exchanger Boilers

Shell and tube heat exchanger boilers use a bundle of tubes to transfer heat between fluid streams. The fluid streams flow on the outside and inside of the tubes, respectively. The heat is transferred from one fluid stream to the other through the walls of the tubes.

- Spiral Heat Exchanger Boilers

Spiral heat exchanger boilers use a spiral-shaped heat exchanger to transfer heat between fluid streams. The fluid streams flow through the spiral, which is made of metal. The heat is transferred from one fluid stream to the other through the metal spiral.

Serve una nuova caldaia?

Applications of Heat Exchanger Boilers

- Space Heating

Heat exchanger boilers are widely used for space heating in residential, commerciale, and industrial buildings. They are ideal for heating large buildings, as they can provide high-temperature water for radiators, underfloor heating, and fan coils.

- Domestic Hot Water Heating

Heat exchanger boilers can also be used for domestic hot water heating. They can provide hot water for showers, bagni, and taps, as well as for washing clothes and dishes.

- Process Heating

Heat exchanger boilers are commonly used for process heating in industries such as chemical processing, food and beverage production, and pharmaceutical manufacturing. They can be used to heat liquids, gases, and solids, and they are ideal for applications where high temperatures are required.

- Heat Recovery

Heat exchanger boilers can be used for heat recovery, which involves capturing heat from an industrial process or other energy source and using it to preheat incoming fluid streams. This can significantly reduce energy consumption and increase efficiency.

What is the working principle of a heat exchanger?

Working principle of heat exchanger boiler

The working principle of a heat exchanger is based on the transfer of heat energy from one fluid to another through a solid or semi-solid surface, such as a metal plate or a tube wall, without direct contact between the two fluids. The heat energy is transferred by conduction, convection, or radiation through the surface, causing a temperature difference between the two fluids.

In a heat exchanger, one fluid stream enters the exchanger as the heating medium and the other fluid stream is the fluid to be heated. The heating medium releases its heat energy to the fluid to be heated, raising its temperature. The two fluids are separated by the heat exchanger surface, and the temperature of the heating medium is maintained by the heat source. The heated fluid then leaves the heat exchanger, ready for use.

This process can occur in both counter-flow and parallel-flow configurations, depending on the type of heat exchanger and the specific application. In counter-flow heat exchangers, the fluid streams flow in opposite directions, maximizing heat transfer efficiency. In parallel-flow heat exchangers, the fluid streams flow in the same direction, but heat transfer is still achieved by the exchange of heat through the surface.

Ricevi preventivi GRATUITI sulla caldaia

Ricevi preventivi GRATUITI per le caldaie locali oggi

Confronta i migliori prezzi

Risparmia denaro sulla tua nuova caldaia oggi!

What are the advantages of heat exchangers?

Advantages of Heat Exchanger Boiler

Heat exchangers offer several advantages over other types of heat transfer systems, Compreso:

- Energy Efficiency: Heat exchangers are designed to transfer heat from one fluid to another with minimal heat loss, making them an energy-efficient solution for many heating applications.

- Space Savings: Heat exchangers are compact and can be designed to fit into small spaces, making them ideal for use in tight spaces or in systems where space is limited.

- Risparmi: Heat exchangers are often less expensive to purchase and operate compared to other types of heating systems, making them a cost-effective solution for many applications.

- Versatility: Heat exchangers can be used in a wide range of applications, including space heating, process heating, domestic hot water heating, and heat recovery. They can also be used with different types of fluids, such as liquids, gases, and solids, making them a versatile solution for many heating needs.

- Reliability: Heat exchangers are durable and reliable, making them a long-lasting solution for many heating applications. They are also easy to maintain and repair, which helps to keep costs low.

- Increased Safety: Heat exchangers are designed to keep the two fluid streams separate, which eliminates the risk of contamination or cross-contamination. This makes them a safer option for many heating applications, especially in food and pharmaceutical industries.

- Improved Process Control: Heat exchangers can be designed to control the temperature and flow rate of the fluid streams, which allows for precise control of the heating process. This improved control leads to higher quality products and increased efficiency.

How much does a heat exchanger boiler replacement cost?

heat exchanger boiler replacement cost

The cost of a heat exchanger boiler replacement can vary widely depending on several factors, such as the type of heat exchanger, the size of the system, the complexity of the installation, and the location. In media, the cost of a heat exchanger boiler replacement can range from $1,500 a $15,000 o più, but it is best to get a detailed estimate from a licensed professional.

It is important to note that a heat exchanger replacement is a significant investment, so it is recommended to have the system professionally inspected to determine the extent of the damage and to evaluate whether a replacement is necessary or if other, less costly, repairs can be made to extend the life of the system. Inoltre, a proper sizing and selection of the heat exchanger based on the heating needs and the application can help to minimize the cost and optimize the performance of the system.

Conclusione

Heat exchanger boilers are an essential component of many sistemi di riscaldamento, providing a cost-effective and efficient way to transfer heat between fluid streams. Whether used for space heating, domestic hot water heating, process heating, or heat recovery, heat exchanger boilers are a versatile and reliable solution. If you are looking for a high-performance heating system, consider a heat exchanger boiler.

Cerco caldaie con lavorazioni sofisticate, ottima qualità?

La caldaia Fangkuai può sempre fornire ciò che desideri.

Caldaia elettrica per acqua calda

Caldaia elettrica per acqua calda  Caldaia a vapore elettrica

Caldaia a vapore elettrica  Caldaia ad acqua calda a gas V6

Caldaia ad acqua calda a gas V6  2023 Guida ai prezzi delle caldaie a gas | Confronto dei costi della caldaia a gas domestica

2023 Guida ai prezzi delle caldaie a gas | Confronto dei costi della caldaia a gas domestica  Le migliori caldaie a gassificazione del legno in vendita | Guida all'acquisto

Le migliori caldaie a gassificazione del legno in vendita | Guida all'acquisto  Prezzi della caldaia combinata elettrica | 2023 Guida all'acquisto

Prezzi della caldaia combinata elettrica | 2023 Guida all'acquisto