Quando si tratta di produrre vapore, ci sono due opzioni comuni: steam boilers e steam generators. Mentre questi termini sono spesso usati in modo intercambiabile, they actually refer to different types of equipment with distinct advantages and disadvantages. In questo articolo, we will compare steam boilers and steam generators and explore their differences, applications, and benefits.

Steam Boilers

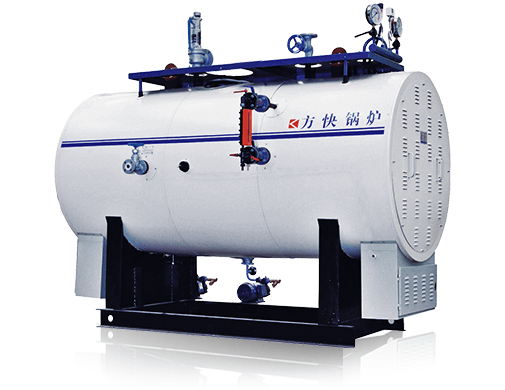

Steam boilers are the most common type of equipment used for steam generation. They are often used in industrial applications to provide heat and power. Steam boilers work by heating water and converting it into steam, which can then be used for various purposes, such as heating buildings, powering turbines, or sterilizing equipment.

Steam boilers typically consist of a pressure vessel, sistema di combustione, water level control system, and safety features such as pressure relief valves and low-water cutoffs. The combustion system can be powered by various fuels, come gas naturale, diesel, o carbone.

One of the primary advantages of steam boilers is their ability to produce large amounts of steam quickly and efficiently. They are also highly flexible and can be used in a variety of applications, from heating buildings to powering industrial processes.

Tuttavia, steam boilers also have some drawbacks. They require a significant amount of space and can be expensive to install and maintain. They also have longer startup times than steam generators, which can be a disadvantage in certain applications.

Serve una nuova caldaia?

Steam Generators

Steam generators are a less common but still important type of equipment used for steam generation. They work by using electric or fuel-powered heating elements to heat water and create steam. Unlike steam boilers, steam generators do not use a combustion system to create heat.

Steam generators are often used in applications where a continuous supply of high-pressure steam is not required, such as in hospitals, laboratories, and small-scale industrial settings. They are also commonly used in other settings where a limited amount of steam is required, such as in cooking, pulizia, and sterilization applications. Per esempio, steam generators may be used in food processing facilities to sterilize equipment or in hospitals to sterilize medical equipment. They may also be used in the production of pharmaceuticals, chemicals, and other products that require precise temperature and pressure control. Steam generators can be an effective and efficient way to produce steam in these applications, offering fast startup times, easy maintenance, and relatively low costs compared to larger steam boilers.

How does a steam generator or boiler work?

Both steam generators and boilers work on the same basic principle of heating water to produce steam, but the way in which they generate steam is different.

A steam generator typically works by heating a small amount of water at a time, which then quickly turns to steam. Water is fed into the steam generator through a valve, and then it is heated by a heating element or burner. As the water heats up, it begins to boil and turn to steam, which is then released from the generator through a pipe or hose. The steam generated by a steam generator is often at a lower pressure than that produced by a boiler, and it is generally not stored for later use.

In contrast, a boiler works by heating a larger amount of water at a time, which is then stored in a tank until it is needed. Water is fed into the boiler through a valve and then heated by a burner or heating element. As the water heats up, it turns into steam, which is then stored in the tank until it is needed. The steam produced by a boiler can be at a higher pressure than that generated by a steam generator, and it can be stored and used later.

Both steam generators and boilers have various components that help to control the temperature, pressione, and flow of steam. These components may include pumps, valves, sensors, and controllers. The design and operation of these components can vary depending on the specific application and the type of generator or boiler being used.

Complessivamente, both steam generators and boilers are used to produce steam for a variety of industrial, commerciale, and residential applications. The choice between a steam generator and a boiler depends on factors such as the required steam pressure and volume, the type of heat source available, and the specific needs and constraints of the application.

Ricevi preventivi GRATUITI sulla caldaia

Ricevi preventivi GRATUITI per le caldaie locali oggi

Confronta i migliori prezzi

Risparmia denaro sulla tua nuova caldaia oggi!

What are the applications of a steam boiler?

Steam boilers are used in a wide range of applications across various industries, Compreso:

- Produzione di energia: Steam boilers are used to generate electricity in power plants. The steam produced by the boiler drives a turbine that generates electricity.

- Processi industriali: Steam is used in a variety of industrial processes, such as textile manufacturing, lavorazione chimica, and food production. Steam boilers are often used to provide the steam necessary for these processes.

- Heating and hot water: Steam boilers can also be used to provide heating and hot water for buildings and other facilities. In many commercial and residential settings, steam boilers are used as a primary source of heat.

- Cleaning and sterilization: Steam is a powerful and effective cleaning agent, and steam boilers are often used to provide high-pressure steam for cleaning and sterilization purposes. Per esempio, steam boilers may be used in hospitals to sterilize medical equipment or in food processing plants to clean machinery.

- Agriculture: Steam boilers are used in the agricultural industry to power equipment such as tractors and threshers.

Complessivamente, steam boilers are a versatile and essential component of many industrial, commerciale, and residential settings. Their ability to produce high-pressure steam makes them an ideal choice for a wide range of applications, from power generation to cleaning and sterilization.

Quale è giusto per te?

When it comes to choosing between a steam boiler and a steam generator, it’s important to consider your specific needs and requirements. If you require a large amount of steam for industrial processes, a steam boiler may be the best option. D'altra parte, if you have limited space and require a small amount of steam, a steam generator may be more suitable.

Insomma, both steam boilers and steam generators have their unique advantages and disadvantages, and the best option for you will depend on your specific requirements. By understanding the differences between these two devices, you can make an informed decision and choose the one that best meets your needs.

Cerco caldaie con lavorazioni sofisticate, ottima qualità?

La caldaia Fangkuai può sempre fornire ciò che desideri.

Caldaia elettrica per acqua calda

Caldaia elettrica per acqua calda  Caldaia a vapore elettrica

Caldaia a vapore elettrica  Caldaia ad acqua calda a gas V6

Caldaia ad acqua calda a gas V6  2023 Guida ai prezzi delle caldaie a gas | Confronto dei costi della caldaia a gas domestica

2023 Guida ai prezzi delle caldaie a gas | Confronto dei costi della caldaia a gas domestica  Le migliori caldaie a gassificazione del legno in vendita | Guida all'acquisto

Le migliori caldaie a gassificazione del legno in vendita | Guida all'acquisto  Prezzi della caldaia combinata elettrica | 2023 Guida all'acquisto

Prezzi della caldaia combinata elettrica | 2023 Guida all'acquisto