Introdução

Before you decide to buy a Caldeira a vapor for your home or business, é importante que você entenda o que é uma caldeira a vapor e como ela funciona. A steam boiler is an apparatus that produces steam from a primary heat source. The primary heat source can be anything from gás natural or oil, para wood, coal or other types of solid fuels (including pellets). After the thermal energy has been converted into water vapor, it produces high-pressure hot water which can then be used to drive turbines and other devices with mechanical energy which in turn drives electrical generators.

What is a steam boiler?

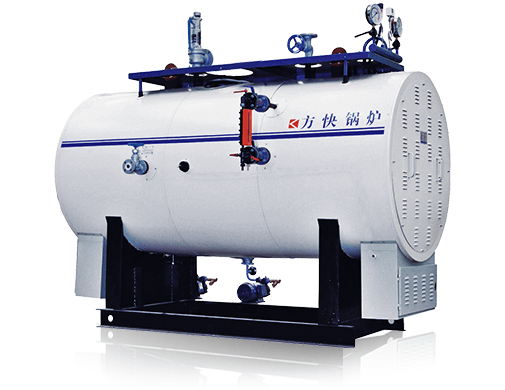

gas steam boiler replacement

A boiler is a closed vessel in which water or other fluid (typically called “liquids”) is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, e industrial steam generation. Power boilers use energy to generate electricity.

Steam power was widely used in the 19th Century when it was first developed by Sir Charles Parsons. It became an important source of electric power during the British Industrial Revolution and it supported large companies such as shipbuilding and steelmaking as well as providing electricity for homes around Britain’s coastlines.

Precisa de uma nova caldeira?

How many types of steam boilers are there?

types of steam boilers

The different types of steam boilers are as follows:

- Fired Boilers: In this type, the heat source is an external combustion. They can be fueled by coal, gás natural, or oil. The fuel is burned inside a furnace to produce heat that goes through radiation tubes and into the water in a pressure vessel where it’s converted into steam.

- Unfired Boilers: This type uses solar energy for heating water by using photovoltaic panels placed on top of an insulated tank filled with water. Pressure is generated by heating up the liquid until it evaporates at 100 graus Celsius (212 F).

What type of boiler is a steam boiler?

Fire Tube steam Boilers

A steam boiler is a heat source that uses the heat energy contained in pressurized steam to generate electricity, produce hot air or water, or even to run machinery.

There are three types of steam boilers:

- Water-tube Boilers – These types of boilers are popular in residential homes because they can be smaller than other types of boilers since they don’t use up much space. They also require fewer repairs and replacements than other types of boilers.

- Fire Tube Boilers – These models have tubes filled with water inside them which lets hot gases escape without burning up too much fuel or losing any pressure. The design helps ensure efficiency when using less fuel while still producing enough power for running equipment like engines on ships or trains between stations while traveling long distances away from home base (or wherever else their final destination might be).

What are the three types of steam?

gas steam boiler price

- Superheated steam is produced at a temperature that exceeds its saturation point. This means the water molecules do not have enough energy to leave the steam and condense into liquid form, which gives it an advantage over other types of boilers because there are fewer by-products created during the heating process. It also releases less heat than wet or dry steam as it expands in volume, which means you can get more work out of each unit than either one. No entanto, this type of boiler is more complex and requires more maintenance than those using other types of boilers for production purposes; it also requires special design considerations when used for heating purposes since its high temperature can damage metal pipes if not properly insulated from heat loss.

- Dry Steam uses a closed-loop system with no external atmospheric pressure (a vacuum). Como tal, there are no gases or air pockets in between molecules and they’ll remain together as long as they’re heated through compression and expansion processes performed by your engine/gearbox combo—that way you get maximum efficiency without wasting time by having them separate out too soon on their own accord before reaching peak performance! Plus you won’t need any additional equipment like condensers or cooling towers which usually increase costs significantly because they require extra maintenance work done regularly within those spaces outside your factory walls where most companies don’t want their workers spending valuable time away from actual production lines while still paying them hourly wages.”

How are steam boilers classified?

Steam boilers are classified by the type of fuel used, type of steam produced, type of heat transfer medium and type of steam generator.

This classification can be further subdivided into various types:

- Stoker-fired or pulverized coal-fired boilers

- Oil-fired boilers (gás ou petróleo)

- Gas-fired boilers (air or oxygen)

What is the principle of steam boiler?

steam boiler work principle

The principle of Caldeira a vapor is a heat engine that converts thermal energy into mechanical energy. The steam boiler is a heat engine that converts thermal energy into mechanical energy by the use of steam as the working fluid.

Steam boilers are used for power generation and process heating, such as in electric power plants, or for industrial processes such as refining petroleum or manufacturing chemicals like sulfuric acid and nitric acid

Procurando caldeiras com fabricação sofisticada, otima qualidade?

A caldeira Fangkuai sempre pode fornecer o que você deseja.

What are the three properties of steam?

custo de substituição da caldeira a vapor

Now that you know how to use a steam boiler, let’s go over the properties of steam.

- Superheating: Steam is typically heated above its boiling point to increase its pressure and convert more heat into mechanical energy. This is achieved by heating it in special vessels called superheaters, which are often used in steam turbines such as those in power plants. The efficiency of a superheater can be increased by using interstage cooling between stages (or between two stages), which allows preheated high-pressure steam to be converted into lower-pressure saturated steam before entering another superheater stage or turbine casing.

- Subcooling: When cooling a saturated vapor stream below its saturation temperature using a sub-cooler, condensation may occur within the subcooled due to pressure drop through the different layers forming inside the cooler tube bundle with each layer having different properties (por exemplo., the subcooled liquid film next to tubes vs vapor bubbles). This process does not result in any net energy transfer as latent heat associated with condensation is equalized by sensible heat generated due to evaporation from tube walls near each layer interface during the heating process when passing through these interfaces; no entanto, it can reduce cross-sectional area requirement for some kinds of refrigeration systems making them more efficient than otherwise would have been possible without this step; por exemplo, see air conditioning system diagram at right where only two compression stages were used instead three required without subcooling

Use of Steam Boiler:

Steam is used for heating (as shown in the figure), and steam is also used for power generation. Steam is a pressurized gas and is an important source of energy throughout the world.

It is widely used for process applications such as:

- Aquecimento

- Geração de energia

- Filtering liquids, chemicals, etc.

Types of Fuels used to operate the steam boiler:

The boiler furnace is designed to burn the fuel in a controlled way and provide thermal energy for heating water. Fuels used to operate steam boilers are:

- Carvão: One of the most common fuels, coal accounts for about 40% of the world’s energy consumption. Coal is mined from mines and also found as surface deposits.

- Natural Gas: A fossil fuel taken from underground reservoirs of natural gas (petroleum), largely in North America and Australia. It is used mainly as a source of heat, light, steam, or power either directly or after processing through gas turbines (for electricity generation) or indirectly through conversion into petrochemical feedstocks such as ethylene and propylene by cracking the hydrocarbons contained within it

Steam Boilers Applications in Different Industries:

- Geração de energia

Steam boilers are used to generate steam for power generation. Steam is mainly produced by burning fossil fuels like coal, gás natural, and oil.

- Chemical and Petrochemical Industry

In this industry, there are many types of steam boilers that are used for various applications such as distillation, drying, and reaction processes. These would include shell-and-tube type caldeiras de condensação, reheating coils in the reactors, etc.

- Refinery & Óleo & Gas Processing Industry: A refinery is a chemical plant where crude oil is processed into various chemicals based on its usage in industry or as fuel like gasoline, diesel oils, etc., through different units such as cracking towers (cracking process), atmospheric distillation towers (distillation process), vacuum distillation towers (vacuum distillation process). In order to make all these processes feasible requires a large amount of heat which can only be generated by means of high-temperature steam if we consider an ideal situation where no external energy sources are available at that time

Advantages of Steam Boiler:

- High efficiency: Steam boilers are highly efficient, and the increase in efficiency is mainly due to the following reasons.

- Low operating costs: The operation of a steam boiler is very simple, which results in low operating costs.

- High reliability: The steam boiler has an excellent reputation for its reliability and safety. It has been used for many years with very few accidents and deaths.

- Low maintenance cost: Maintenance is not difficult because there are few moving parts compared with other types of boilers, so there’s less wear and tear on your system, resulting in lower maintenance costs over time!

- High power density: With high power density (kW/L), you can achieve higher output at a lower cost than conventional fossil fuel-based processes such as those involving natural gas or oil burners which require high capital investment upfront but produce only small amounts per hour due to limited supply capacity available at any given time; This means that if your business needs more energy throughout each day (ease fatigue), then this type may be best suited!

How to Increase Boiler Efficiency:

Steam boilers are used in a wide range of industries, Incluindo:

- Geração de energia

- Chemical processing

- Pulp and paper manufacturing

- Food processing

Procurando caldeiras com fabricação sofisticada, otima qualidade?

A caldeira Fangkuai sempre pode fornecer o que você deseja.

Conclusão

Steam boilers are a type of heat engine that uses steam as their working fluid. They are usually powered by burning fossil fuels like coal, gás natural, or oil and can be used in many different types of industries to provide heat or power. The main purpose behind using this type of equipment is that it can provide a continuous heat supply at high temperatures which means no need for reheating before use, unlike other types such as electric heating elements which require constant heating up again after each use.

Caldeira elétrica de água quente

Caldeira elétrica de água quente  Caldeira elétrica a vapor

Caldeira elétrica a vapor  Caldeira de água quente a gás V6

Caldeira de água quente a gás V6  2023 Guia de preços de caldeiras a gás | Comparando custos de caldeiras a gás domésticas

2023 Guia de preços de caldeiras a gás | Comparando custos de caldeiras a gás domésticas  Melhores caldeiras de gaseificação de madeira à venda | guia de compra

Melhores caldeiras de gaseificação de madeira à venda | guia de compra  Preços da Caldeira Combi Elétrica | 2023 guia de compra

Preços da Caldeira Combi Elétrica | 2023 guia de compra