Welcome to our comprehensive guide to Kesseltausch. Wenn Sie über den Austausch Ihres Heizkessels nachdenken, Sie sind an der richtigen Stelle. In diesem Artikel, we will provide you with all the essential information you need to know about boiler replacement, including its cost, Vorteile, and the installation process. By the end of this guide, you’ll be well-equipped to make an informed decision and find the best boiler replacement solution for your needs.

Steam Boiler Replacement Cost

The average cost of a steam boiler replacement ranges from $6,772 zu $12,441. Jedoch, the overall cost of replacing a boiler can vary depending on factors such as the size and type of the boiler, with prices ranging from $4,290 zu $10,070. The average boiler replacement cost is around $7,938 und $8,300 , with the following factors affecting cost:

- Size of the system: The larger the system, the more expensive it will be to replace. The cost will depend on the boiler’s capacity, measured in BTUs (Britische Thermaleinheiten) or horsepower.

- Type of fuel: Steam boilers can run on various fuels, such as natural gas, Öl, or electricity. The type of fuel used can affect the cost of the new boiler and the cost of operation.

- Complexity of installation: The installation process can vary in complexity, depending on factors such as the location of the boiler, the configuration of the piping system, and the need for additional components like pumps or valves.

- Marke: While most boilers fall within the same price range regardless of brand, some high-tech brands cost more.

Brauche einen neuen Kessel?

Boiler Replacement Cost by Size

Boiler size is commonly measured in BTU, or British thermal units—the amount of heat energy the machine is capable of producing.The size of your boiler plays a significant role in determining the replacement cost. Allgemein, larger boilers are more expensive due to the increased materials and components required. Zum Beispiel, a small residential boiler may cost between $2,500 und $5,000, while a larger commercial boiler can cost anywhere from $10,000 zu $50,000 oder mehr.

| Home Size (sq. ft.) | Boiler Capacity (BTU) | Price |

|---|---|---|

| 1,000 | 30,000–45,000 | $4,030–$6,180 |

| 1,500 | 45,000–68,000 | $4,450–$6,840 |

| 1,750 | 53,000–79,000 | $4,590–$7,050 |

| 2,000 | 60,000–90,000 | $5,080–$7,800 |

| 2,500 | 75,000–113,000 | $5,630–$8,640 |

Boiler Replacement Cost by Fuel Type

The type of fuel your boiler uses also impacts the replacement cost. Here’s a breakdown of average costs for different fuel types:

- Gas: Natural gas boilers are typically more affordable, with prices ranging from $3,000 zu $10,000.

- Öl: Oil-fired boilers can be more expensive, with costs between $4,000 und $12,000.

- Elektrisch: Electric boilers can cost anywhere from $1,500 zu $6,000, depending on size and efficiency.

| Treibstoffart | Average Cost Range (USD) |

|---|---|

| Natural Gas | $3,500 – $8,000 |

| Propane | $4,000 – $10,000 |

| Öl | $4,500 – $11,000 |

| Elektrisch | $2,000 – $5,000 |

| Biomasse | $6,000 – $15,000 |

| Wood | $3,500 – $9,000 |

| Kohle | $4,500 – $11,000 |

Holen Sie sich KOSTENLOSE Angebote für Heizkessel

Holen Sie sich noch heute KOSTENLOSE lokale Boiler-Angebote

Vergleichen Sie die besten Preise

Sparen Sie noch heute Geld bei Ihrem neuen Heizkessel!

Cost of Boiler Replacement by Brand

The brand of your boiler can also influence the steam boiler replacement cost. Some popular boiler brands and their price ranges include:

| Marke | Average Cost Range (USD) |

|---|---|

| Worcester Bosch | $3,500 – $9,000 |

| Vaillant | $4,000 – $10,000 |

| Buderus | $4,500 – $11,000 |

| Viessmann | $5,000 – $12,000 |

| Ideal | $3,500 – $9,000 |

| Navien | $4,000 – $10,000 |

| Glühwürmchen | $3,500 – $9,000 |

| Potterton | $3,500 – $9,000 |

| Biasi | $3,500 – $9,000 |

| Vokera | $3,500 – $9,000 |

Boiler Replacement Cost of Installation

The cost of installation for a boiler replacement typically ranges from $1,000 zu $3,500. The price may vary depending on factors such as the complexity of the installation, the need for additional piping or venting, and local labor rates.

| Treibstoffart | Installation Costs |

|---|---|

| Gas | $4,000 – $7,000 |

| Öl | $5,000 – $9,000 |

| Elektrisch | $1,000 – $6,000 |

| Biomasse | $12,000 – $25,000 |

| Propane | $3,000 – $5,000 |

Boiler Replacement Cost by System Type

In addition to fuel type and brand, residential boilers can be categorized based on how they heat and store water. Boilers can be classified as conventional, System, or combination (combi) Kessel, depending on their water storage methods. They may use either hot water or steam to generate heat. Furthermore, most high-efficiency models are condensing boilers, as opposed to standard efficiency, non-condensing boilers. We will elaborate on these distinctions below, but it’s important to understand how these classifications impact boiler prices. Keep in mind that a boiler can belong to more than one of these categories; for instance, you could have a conventional, non-condensing steam boiler.

| Type of Boiler | Price |

|---|---|

| Conventional | $1,200–$5,000 |

| System | $3,000–$5,500 |

| Combi | $2,600–$6,800 |

| Hot water | $1,200–$8,000 |

| Dampf | $2,500–$9,000 |

| Condensing | $1,900–$7,000 |

| Non-condensing | $1,200–$5,000 |

Other Factors in Boiler Replacement Costs

Apart from the cost of the boiler itself and the labor required for installation, you may encounter several additional expenses during the process:

- Manual J inspection: Instead of making rough estimates, HVAC professionals can determine the precise BTU requirements to heat your home by considering factors such as climate, insulation, types of doors and windows, and even the color of your roof. This process is known as a Manual J inspection and typically costs around $100.

- Switching fuel types: If your home is configured for one fuel type but your new boiler uses another, you will likely incur extra material and labor costs. The same applies if you want to change the boiler’s location within your home.

- Permits: In many areas, HVAC installations require a permit, which can cost anywhere from $50 zu $300.

- Insulation: During a Manual J inspection, the contractor may discover that upgrading your home’s insulation allows you to use a smaller boiler. A better-insulated home is more energy-efficient and therefore less expensive to heat.

- Repair: If a boiler replacement is not necessary, repairing it is typically a more cost-effective option. According to a survey by Consumer Reports, homeowners paid an average of $391 for boiler repairs in 2023.

When budgeting for a boiler replacement, it’s essential to consider these additional expenses and obtain multiple quotes from different contractors to ensure you’re getting the best value and quality for your investment.

Holen Sie sich KOSTENLOSE Angebote für Heizkessel

Holen Sie sich noch heute KOSTENLOSE lokale Boiler-Angebote

Vergleichen Sie die besten Preise

Sparen Sie noch heute Geld bei Ihrem neuen Heizkessel!

Types of Boilers

There are several types of boilers available, including combi boilers, Systemkessel, and regular boilers. Each type has its own advantages and disadvantages, so it’s essential to choose the right one for your specific needs.

- Conventional BoilersConventional boilers consist of a separate hot water storage cylinder and a cold-water storage tank. They heat the water in the storage cylinder, which then supplies hot water to the taps and radiators. These boilers are suitable for homes with multiple bathrooms and a high demand for hot water.Advantages:

- Can provide hot water to multiple taps simultaneously.

- Compatible with older radiator systems.

- Suitable for homes with low water pressure.

Nachteile:

- Requires space for a hot water cylinder and a cold-water storage tank.

- Hot water supply can run out and requires time to reheat.

- Less energy-efficient compared to system and combi boilers.

- System BoilersSystem boilers are similar to conventional boilers in that they also use a hot water storage cylinder. Jedoch, they don’t require a cold-water storage tank, as they take water directly from the mains supply. System boilers are more energy-efficient and compact compared to conventional boilers.Advantages:

- Provides a constant supply of hot water to multiple taps simultaneously.

- No need for a cold-water storage tank, saving space.

- More energy-efficient compared to conventional boilers.

Nachteile:

- Requires space for a hot water cylinder.

- Hot water supply can run out and requires time to reheat.

- Less energy-efficient compared to combi boilers.

- Combination (Combi) BoilersCombi boilers are single-unit systems that heat water directly from the cold mains supply, providing hot water on demand without the need for a hot water storage cylinder or a cold-water storage tank. They are the most energy-efficient and compact option among the three types of boilers.Advantages:

- Instantaneous hot water supply without the need for a storage cylinder.

- Saves space due to the absence of a hot water cylinder and cold-water storage tank.

- Highly energy-efficient, reducing energy bills and carbon emissions.

Nachteile:

- Begrenzter Warmwasserdurchfluss, making it less suitable for homes with multiple bathrooms.

- Not compatible with older radiator systems that require a separate hot water storage.

- Requires good water pressure from the mains supply.

- Hot Water BoilersHot water boilers, also known as hydronic boilers, heat water to a specific temperature and circulate it through a closed-loop system of pipes, Heizkörper, oder Fußleistenheizungen. The heated water transfers its heat to the surrounding environment, providing warmth to the space.Advantages:

- Quiet operation, as there is no steam or boiling water involved.

- Lower operating pressure, making them safer.

- Greater energy efficiency due to lower heat loss.

- Easier to maintain and repair, with fewer components and less complexity.

- More versatile, as they can be used for radiant floor heating, baseboard heating, and forced air systems.

Nachteile:

- Slower to heat up the space, as they rely on the circulation of hot water.

- Occupies more space due to the need for a separate hot water storage tank or an expansion tank.

- Requires a pump to circulate the hot water through the system.

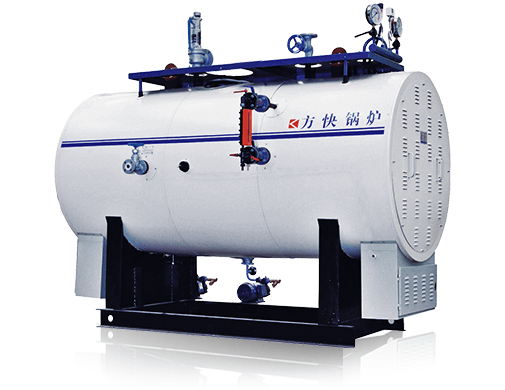

- DampfkocherSteam boilers heat water until it turns into steam, which then travels through a system of pipes and radiators to provide heat. The steam condenses back into water, which returns to the boiler to be reheated.Advantages:

- Faster to heat up the space, as steam carries a large amount of heat energy.

- No need for a pump, as the steam naturally rises through the system due to its lower density than air.

- Can operate at higher temperatures and pressures, making them suitable for industrial applications.

- Occupies less space, as there is no need for a separate hot water storage tank.

Nachteile:

- Noisy operation due to the boiling water and the movement of steam through the system.

- Higher operating pressure, which can pose safety risks if not properly maintained.

- Less energy-efficient due to higher heat loss and the energy required to convert water into steam.

- More complex and requires more maintenance, as there are more components and a higher risk of corrosion and scaling.

- Condensing BoilersCondensing boilers are designed to capture and reuse the heat from the flue gases that would otherwise be lost in a non-condensing boiler. They achieve this by using a heat exchanger to extract heat from the flue gases, which condense into water vapor, releasing latent heat. This heat is then used to preheat the cold water entering the boiler, increasing the overall efficiency.Advantages:

- Higher energy efficiency: Condensing boilers can achieve efficiencies of up to 90-98%, compared to 70-80% for non-condensing boilers.

- Lower energy bills: Due to their higher efficiency, condensing boilers consume less fuel, resulting in lower energy bills.

- Reduzierte Kohlenstoffemissionen: Using less fuel also means producing fewer greenhouse gas emissions, making condensing boilers more environmentally friendly.

- Quieter operation: The heat exchanger in a condensing boiler helps to dampen the noise from the combustion process.

Nachteile:

- Higher initial cost: Condensing boilers are generally more expensive to purchase and install than non-condensing boilers.

- More complex: The additional components, such as the heat exchanger and condensate drain, can make condensing boilers more complex and potentially more challenging to maintain.

- Requires proper venting: Condensing boilers produce acidic condensate, which must be properly drained and vented to avoid damage to the boiler or the building.

- Non-Condensing BoilersNon-condensing boilers are traditional boilers that do not have a heat exchanger to capture and reuse heat from the flue gases. As a result, the heat in the flue gases is lost through the boiler’s exhaust, making them less energy-efficient compared to condensing boilers.Advantages:

- Lower initial cost: Non-condensing boilers are generally less expensive to purchase and install than condensing boilers.

- Simpler design: With fewer components, non-condensing boilers are often easier to maintain and repair.

- Less sensitive to installation conditions: Non-condensing boilers do not produce acidic condensate, which means they are less sensitive to venting and drainage issues.

Nachteile:

- Lower energy efficiency: Non-condensing boilers typically have efficiencies of 70-80%, which is lower than the 90-98% efficiency of condensing boilers.

- Higher energy bills: Due to their lower efficiency, non-condensing boilers consume more fuel, resulting in higher energy bills.

- Increased carbon emissions: Using more fuel also means producing more greenhouse gas emissions, making non-condensing boilers less environmentally friendly.

- Standard Boilers (Non-Condensing Boilers)Standard boilers are traditional boilers that do not have a heat exchanger to capture and reuse heat from the flue gases. As a result, the heat in the flue gases is lost through the boiler’s exhaust, making them less energy-efficient compared to high-efficiency boilers.Advantages:

- Lower initial cost: Standard boilers are generally less expensive to purchase and install than high-efficiency boilers.

- Simpler design: With fewer components, standard boilers are often easier to maintain and repair.

- Less sensitive to installation conditions: Standard boilers do not produce acidic condensate, which means they are less sensitive to venting and drainage issues.

Nachteile:

- Lower energy efficiency: Standard boilers typically have efficiencies of 70-80%, which is lower than the 90-98% efficiency of high-efficiency boilers.

- Higher energy bills: Due to their lower efficiency, standard boilers consume more fuel, resulting in higher energy bills.

- Increased carbon emissions: Using more fuel also means producing more greenhouse gas emissions, making standard boilers less environmentally friendly.

- High-Efficiency Boilers (Condensing Boilers)Hocheffiziente Heizkessel, also known as condensing boilers, are designed to capture and reuse the heat from the flue gases that would otherwise be lost in a standard boiler. They achieve this by using a heat exchanger to extract heat from the flue gases, which condense into water vapor, releasing latent heat. This heat is then used to preheat the cold water entering the boiler, increasing the overall efficiency.Advantages:

- Higher energy efficiency: High-efficiency boilers can achieve efficiencies of up to 90-98%, compared to 70-80% for standard boilers.

- Lower energy bills: Due to their higher efficiency, high-efficiency boilers consume less fuel, resulting in lower energy bills.

- Reduzierte Kohlenstoffemissionen: Using less fuel also means producing fewer greenhouse gas emissions, making high-efficiency boilers more environmentally friendly.

- Quieter operation: The heat exchanger in a high-efficiency boiler helps to dampen the noise from the combustion process.

Nachteile:

- Higher initial cost: High-efficiency boilers are generally more expensive to purchase and install than standard boilers.

- More complex: The additional components, such as the heat exchanger and condensate drain, can make high-efficiency boilers more complex and potentially more challenging to maintain.

- Requires proper venting: High-efficiency boilers produce acidic condensate, which must be properly drained and vented to avoid damage to the boiler or the building.

Signs You Need a Boiler Replacement

Some signs that it’s time for a boiler replacement include:

- Frequent breakdowns and repairs

- Rising energy bills

- Inconsistent heating throughout your home

- Your boiler is more than 15 years old

- Visible signs of corrosion or leaks

How To Replace a Boiler

When it’s time to replace your boiler, follow these steps:

- Consult a professional: Speak with a licensed HVAC professional to determine the best boiler type and size for your needs.

- Get quotes: Obtain quotes from multiple contractors to compare prices and services.

- Choose a contractor: Select a reputable contractor with experience in boiler replacement.

- Schedule the installation: Arrange a convenient time for the contractor to perform the installation.

- Maintain your new boiler: Regular maintenance is crucial for the longevity and efficiency of your new boiler, so be sure to schedule routine checkups and cleanings.

Abschließend, the steam boiler replacement cost can vary based on several factors, including size, Treibstoffart, brand, and system type. It’s essential to consult with a professional to determine the best option for your specific needs and budget.

Auf der Suche nach Kesseln mit anspruchsvoller Fertigung, großartige Qualität?

Der Fangkuai-Kessel kann immer liefern, was Sie wollen.

Elektrischer Warmwasserboiler

Elektrischer Warmwasserboiler  Elektrischer Dampfkessel

Elektrischer Dampfkessel  V6 gasbefeuerter Heißwasserboiler

V6 gasbefeuerter Heißwasserboiler  2023 Preisführer für Gaskessel | Vergleich der Kosten für Gaskessel zu Hause

2023 Preisführer für Gaskessel | Vergleich der Kosten für Gaskessel zu Hause  Die besten Holzvergaserkessel zum Verkauf | Einkaufsführer

Die besten Holzvergaserkessel zum Verkauf | Einkaufsführer  Preise für elektrische Kombikessel | 2023 Einkaufsführer

Preise für elektrische Kombikessel | 2023 Einkaufsführer