Power plant boilers are an integral component of power generation plants. Son los encargados de convertir la energía generada por el combustible en vapor, which in turn drives turbines to generate electricity. Here’s a comprehensive guide to power plant boilers, covering their types, combustibles, maintenance, seguridad, and environmental impact.

What is a power plant boiler?

A power plant boiler is a critical component of a power generation plant. It’s a large vessel that produces steam, which is used to turn turbines that generate electricity. A boiler has several components, including a furnace, water-cooled walls, and superheaters, which help to convert water into vapor de alta presión.

How does a power plant boiler work?

A power plant boiler works by heating water to produce high-pressure steam, which drives turbines to generate electricity. The fuel used to heat the water varies, but it’s usually coal, gas natural, o aceite. The steam produced by the boiler is then sent to a turbine, which drives a generator to produce electricity.

Necesito una nueva caldera?

What are the different types of power plant boilers?

There are several types of power plant boilers that are used to generate electricity. Each type of boiler has its own unique characteristics and advantages, and the choice of boiler depends on a variety of factors, such as the type of fuel being used, the power plant’s capacity, and the cost of the boiler. Here are some of the most common types of power plant boilers:

- Pulverized coal-fired boilers: These are the most commonly used boilers in power plants and are designed to burn coal in a pulverized form. In these boilers, the coal is ground into a fine powder and blown into the combustion chamber, where it burns to produce high-pressure steam.

- Circulating fluidized bed boilers: These boilers use a process called fluidization to burn coal or biomass in a suspended state. In these boilers, the fuel is fed into a bed of sand-like material, and air is blown through the bed to suspend the fuel particles in the air. This creates a turbulent mixing of the fuel and air, which helps to improve combustion efficiency.

- Heat recovery steam generators (HRSGs): These boilers are used in combined cycle power plants, where they capture the waste heat from gas turbines and use it to produce steam. The steam can then be used to drive a steam turbine and generate additional electricity.

- Nuclear reactors: These boilers use nuclear fuel, such as uranium or plutonium, to produce steam, which is used to drive turbines and generate electricity. Nuclear reactors are highly efficient and produce large amounts of electricity, but they require extensive safety measures to prevent accidents.

- Solar thermal power plants: These power plants use mirrors or lenses to focus sunlight on a central receiver, which is used to heat a fluid, such as molten salt, to produce steam. The steam is then used to drive a turbine and generate electricity. Solar thermal power plants are still in the experimental stage and are not yet widely used.

En resumen, there are several types of power plant boilers, each with its own unique characteristics and advantages. The choice of boiler depends on a variety of factors, such as the type of fuel being used, the power plant’s capacity, and the cost of the boiler. Understanding the different types of boilers and their benefits is essential for making informed decisions about power plant design and operation.

Obtenga un precio fijo en línea en 20 segundos:

What kind of fuel is used in power plant boilers?

Power plant boilers can be fueled by a variety of materials, including coal, gas natural, aceite, biomass, and waste products. The type of fuel used depends on several factors, including availability, costo, and environmental impact.

How efficient are power plant boilers?

Power plant boilers can have efficiencies ranging from 30% para acabar 90%, depending on the type of boiler and the fuel used. Boilers with higher efficiencies are more expensive but can result in significant cost savings over the life of the boiler.

What are the main components of a power plant boiler?

The main components of a power plant boiler include a furnace, water-cooled walls, superheaters, economizers, and air preheaters. These components work together to convert water into high-pressure steam, which is used to drive turbines and generate electricity.

How are power plant boilers maintained?

Power plant boilers require regular maintenance to ensure they operate efficiently and safely. Maintenance tasks can include cleaning, inspection, and repair of various components. Regular maintenance can help prevent breakdowns and extend the life of the boiler.

What are the safety considerations for power plant boilers?

Power plant boilers can be dangerous if not properly maintained and operated. Safety considerations include the risk of explosion, fire, and carbon monoxide poisoning. Proper training, safety equipment, and procedures are necessary to ensure the safety of personnel and the public.

How do power plant boilers impact the environment?

Power plant boilers puede tener un impacto significativo en el medio ambiente, incluida la contaminación del aire, la contaminación del agua, y emisiones de gases de efecto invernadero. El tipo de combustible utilizado, la eficiencia de la caldera, y la tecnología de control de emisiones utilizada pueden afectar el impacto ambiental de la caldera.

¿Cuál es la vida útil de una caldera de planta de energía??

La vida útil de la caldera de una central eléctrica depende de varios factores, incluyendo el tipo de caldera, la calidad de los materiales utilizados en la construcción, y la frecuencia y calidad del mantenimiento. Típicamente, Las calderas de las centrales eléctricas pueden durar desde 20 a 50 años, pero esto puede variar dependiendo de los factores mencionados anteriormente.

Conclusión

En conclusión, Las calderas de las centrales eléctricas son un componente crítico de las plantas de generación de energía., convertir el combustible en vapor para generar electricidad. Comprender los diferentes tipos de calderas, combustibles, requisitos de mantenimiento, consideraciones de seguridad, y el impacto ambiental es fundamental.

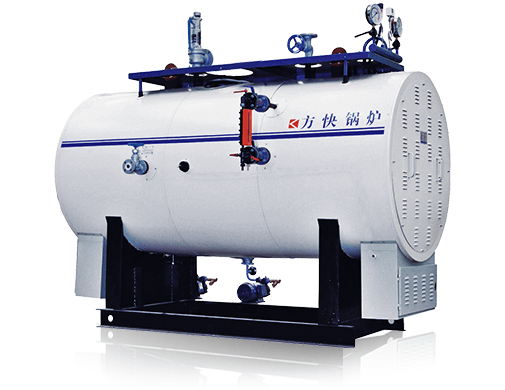

Buscando calderas con fabricación sofisticada, gran calidad?

La caldera Fangkuai siempre puede proporcionar lo que desea.

Caldera de agua caliente eléctrica

Caldera de agua caliente eléctrica  Caldera de vapor eléctrica

Caldera de vapor eléctrica  Caldera de agua caliente a gas V6

Caldera de agua caliente a gas V6  2023 Guía de precios de calderas de gas | Comparación de los costos de las calderas de gas domésticas

2023 Guía de precios de calderas de gas | Comparación de los costos de las calderas de gas domésticas  Las mejores calderas de gasificación de madera a la venta | Guía de compra

Las mejores calderas de gasificación de madera a la venta | Guía de compra  Precios de calderas mixtas eléctricas | 2023 Guía de compra

Precios de calderas mixtas eléctricas | 2023 Guía de compra